The BOM products (Product Parts and Raw Materials) and also products with BOMs can have multiple inventories.

FIRST STEPS

Something that you should have clear from the beginning, is that when you add multiple inventories to any product and, at the same time, you add linked BOMs to the same product (and the BOM stock control option is enabled from ATUM settings), the only inventory that will have its stock calculated according to its BOM’s stock is the “Main Inventory”. All the other inventories will work as "produced" inventories and they won't be part of the BOM tree.

So if the “Main Inventory” is used on any purchase, all its BOMs stocks will be reduced automatically, but if any of the “custom” inventories are used, it will reduce just the stock for the used inventory.

Let's describe a practical example.

Imagine that you have a final product with Multi-Inventory that is composed of these BOMs:

- 1 unit of a Raw Material

- 1 unit of a Product Part

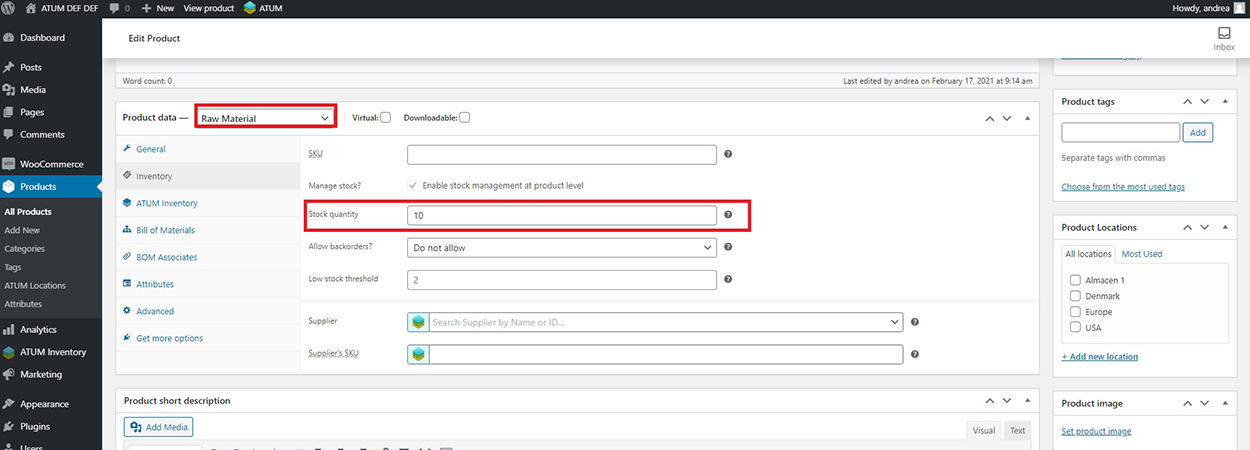

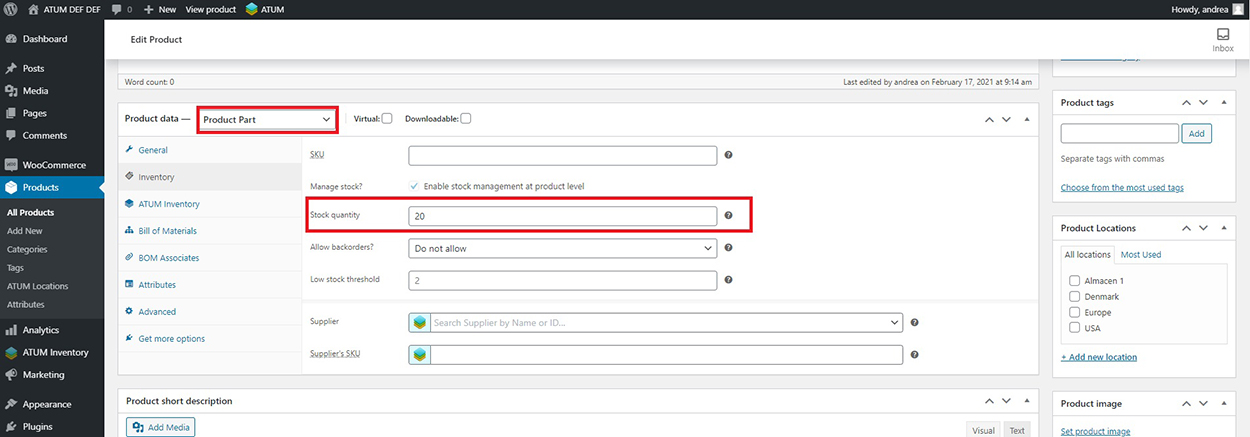

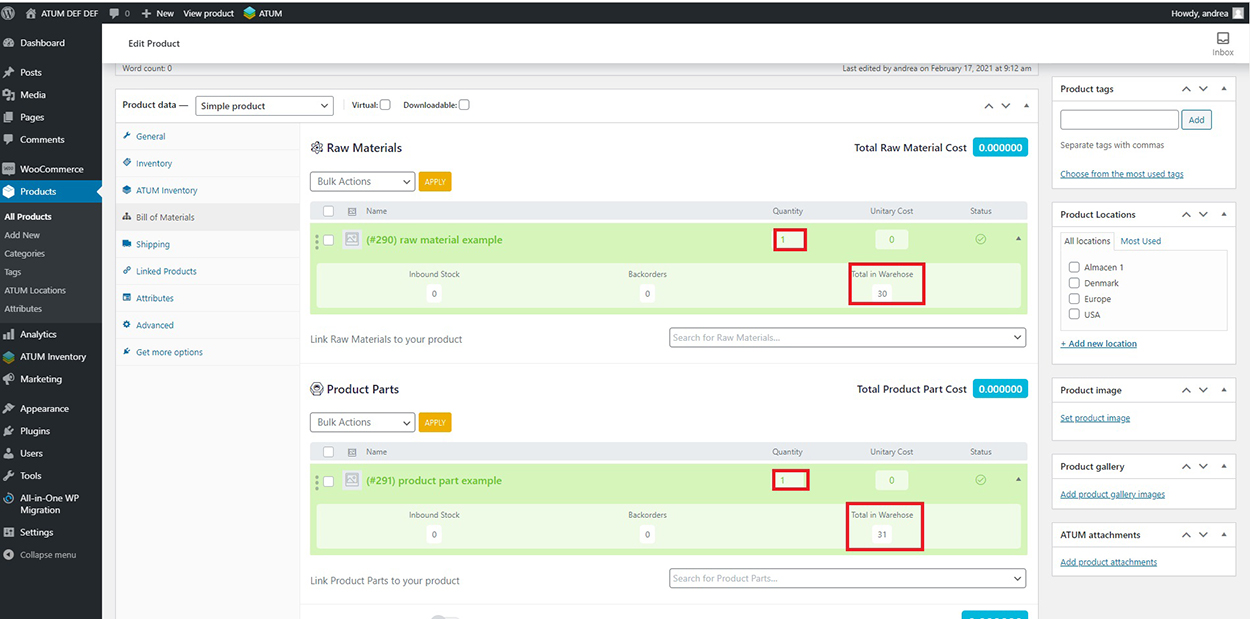

These are the settings of both BOMs:

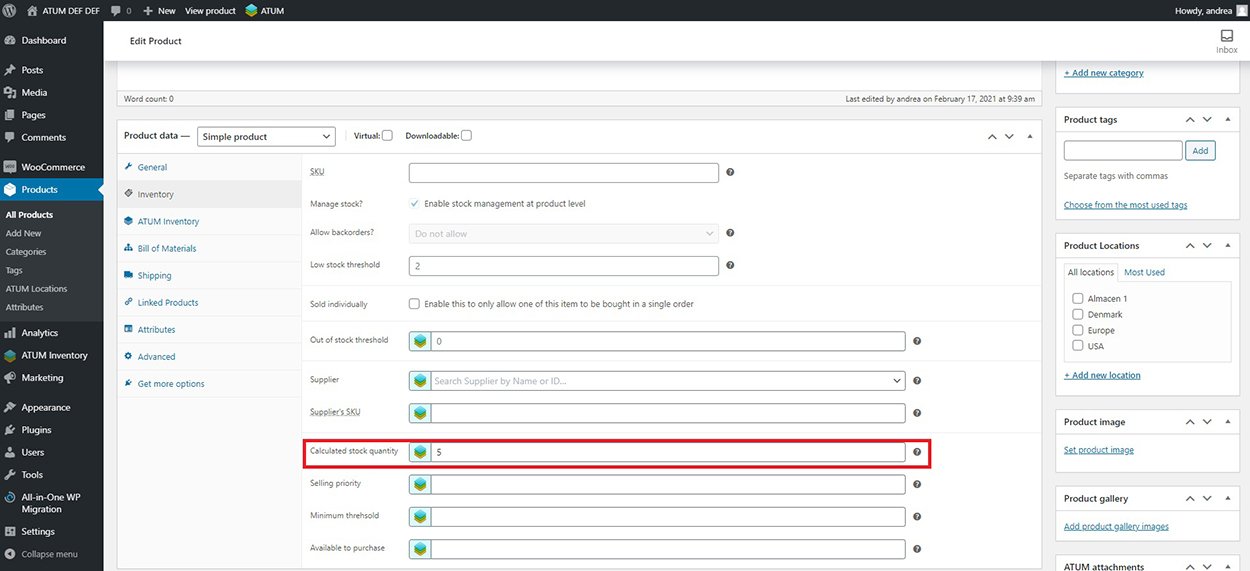

A RAW MATERIAL 1 (quantity: 10)

A PRODUCT PART 1 (quantity: 20)

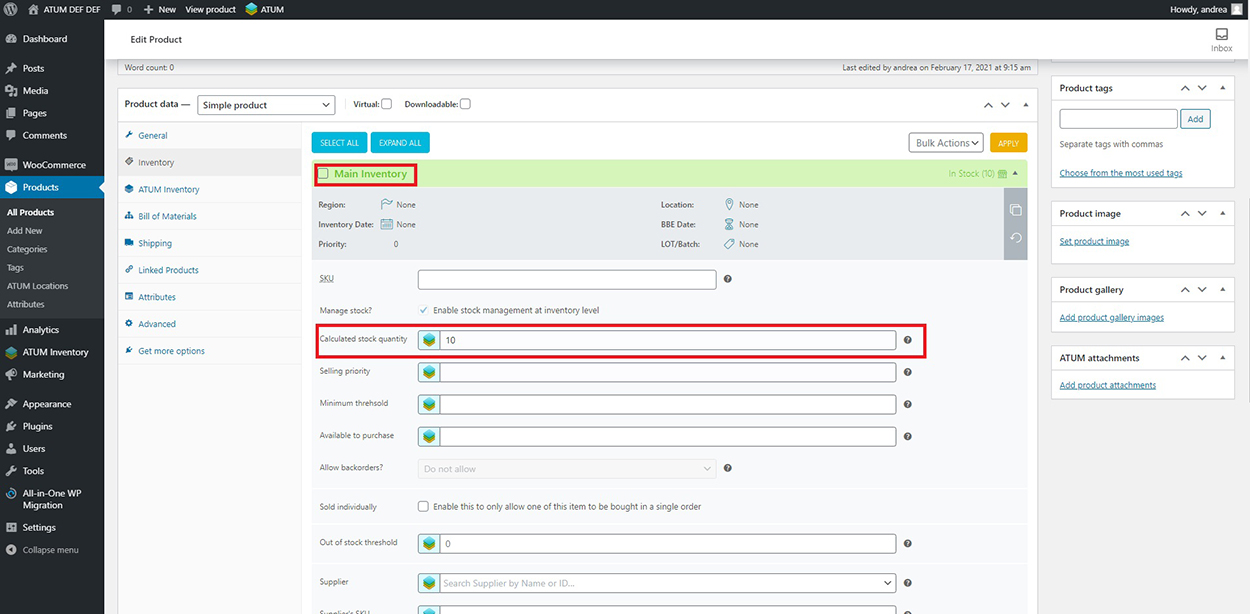

So, the calculated stock for the Main Inventory of the final product will be 10

And if you create additional inventories you will need to add their stock manually.

EXAMPLES OF INTEGRATIONS

Let's see some different scenarios to see how it works:

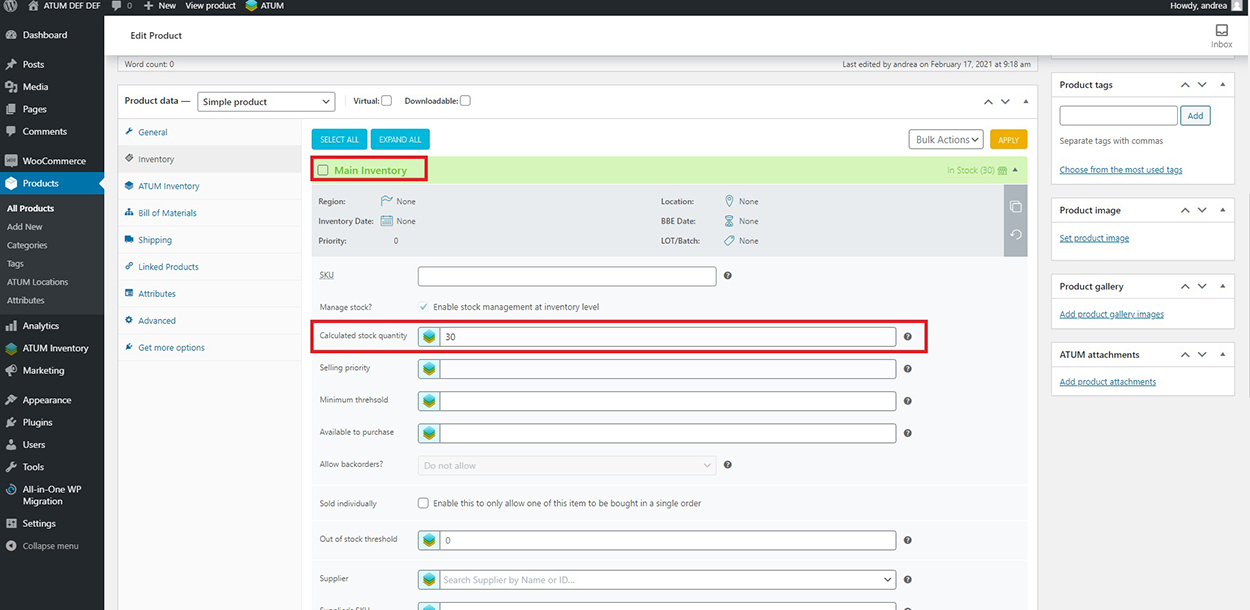

SCENARIO 1. When the product is Multi-Inventory, but BOMs aren't.

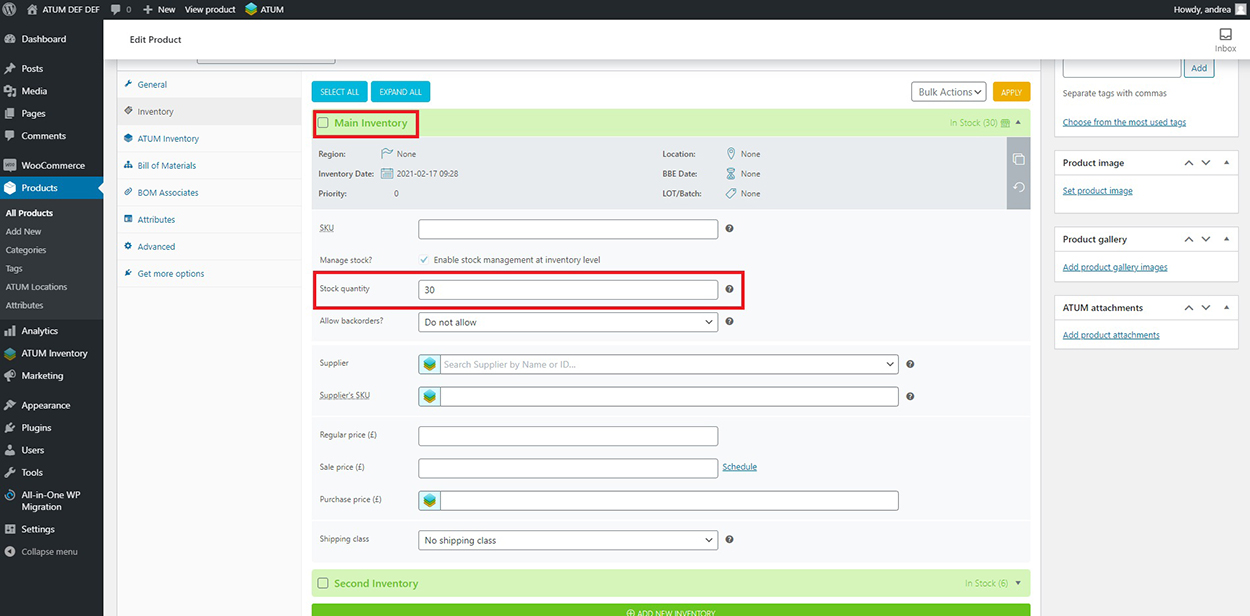

In this case, the stock quantity of the product is 30.

And the calculated automatically stock quantity is only applied to the Main Inventory.

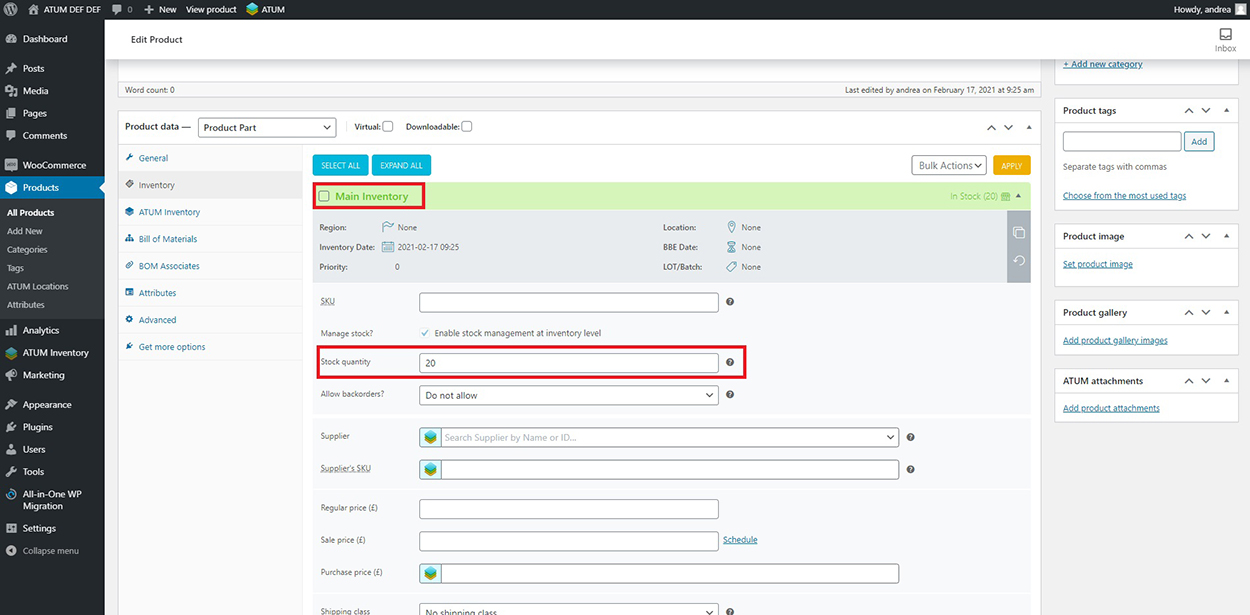

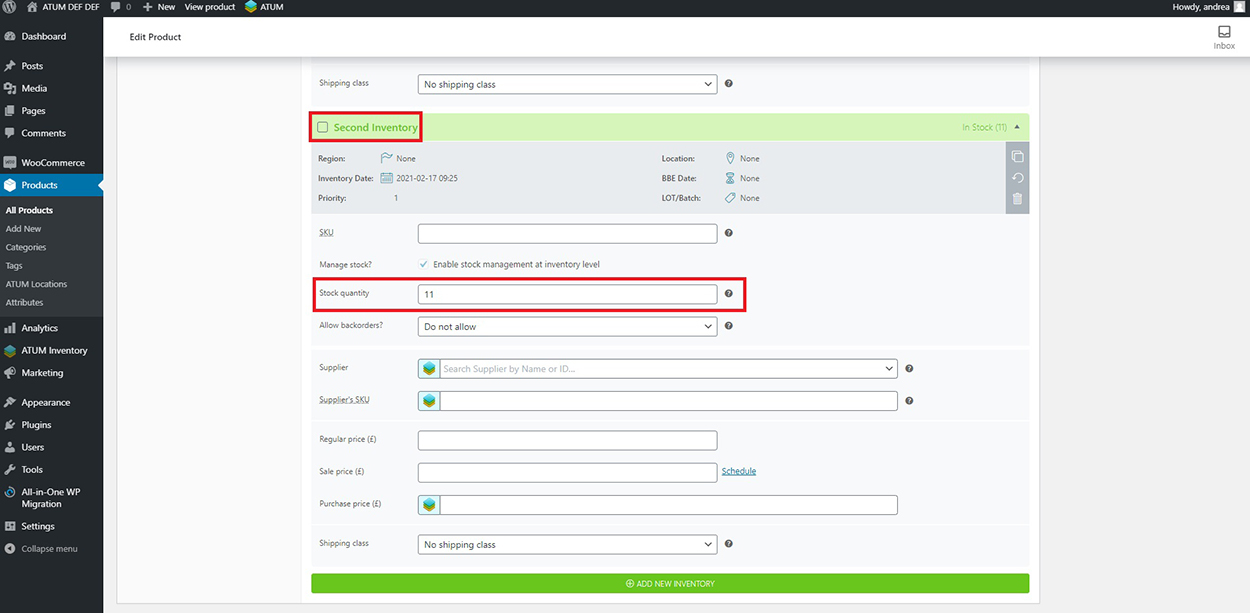

SCENARIO 2. When the product is not Multi-Inventory, but BOMs are.

Observe the stock quantity value in inventories of the Product Part:

MAIN INVENTORY: 20

SECOND INVENTORY: 11

In this case, the total stock quantity of the product part is 31.

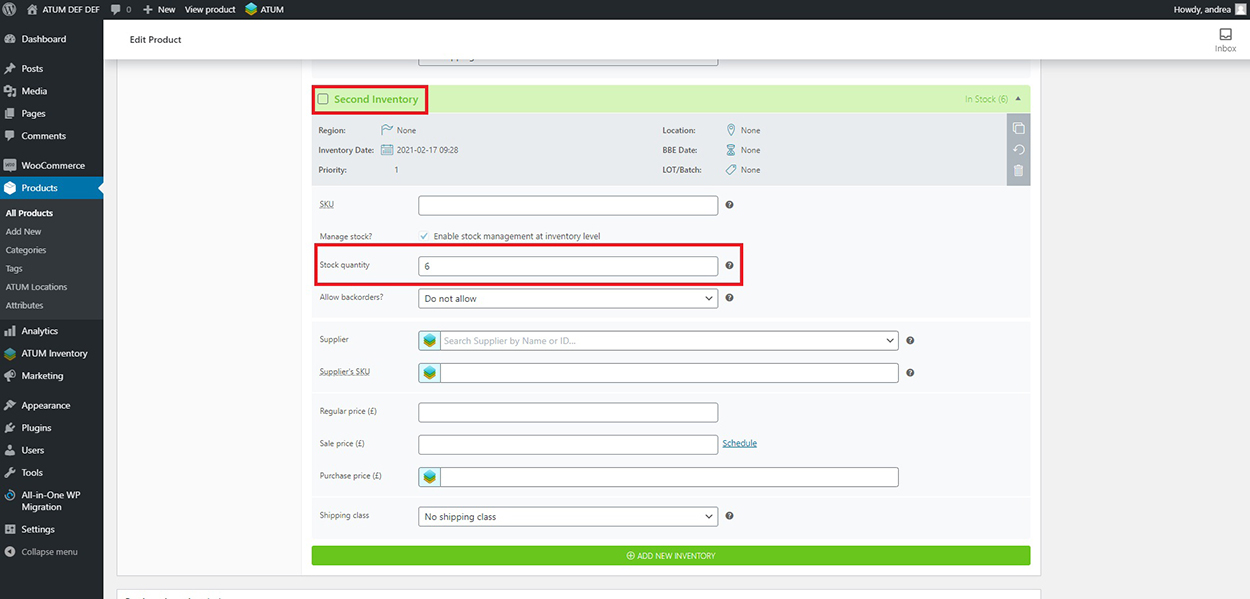

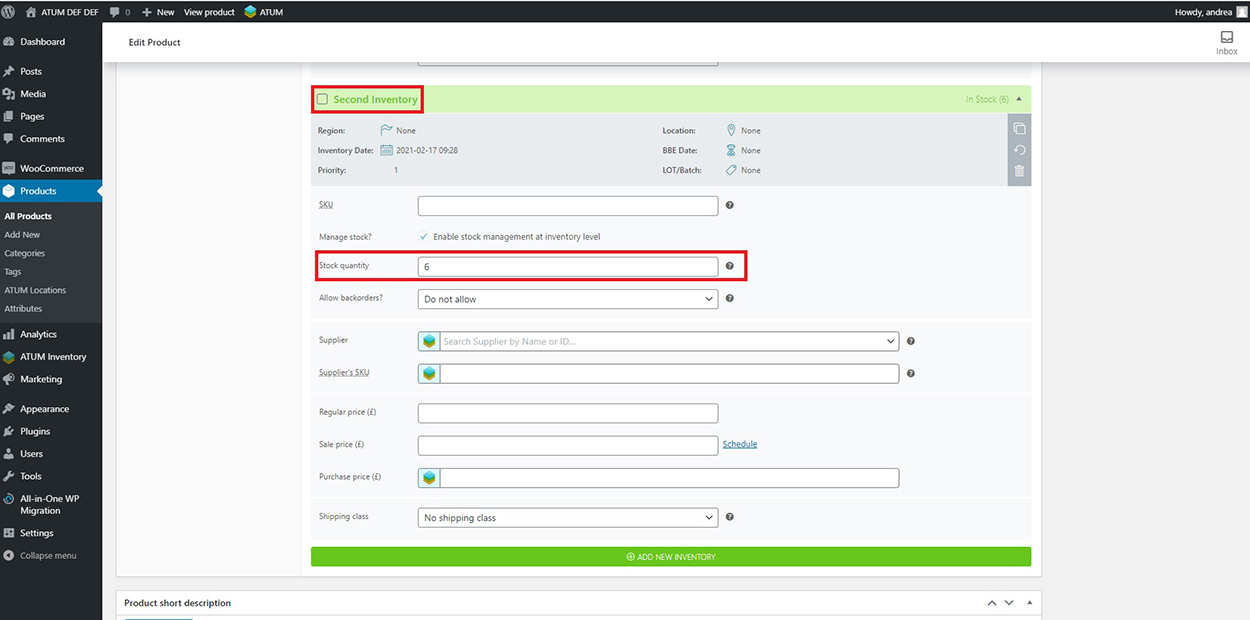

Now, observe the stock quantity value of the Raw Material:

MAIN INVENTORY: 30

SECOND INVENTORY: 6

In this case, the total stock quantity of the raw material is 36.

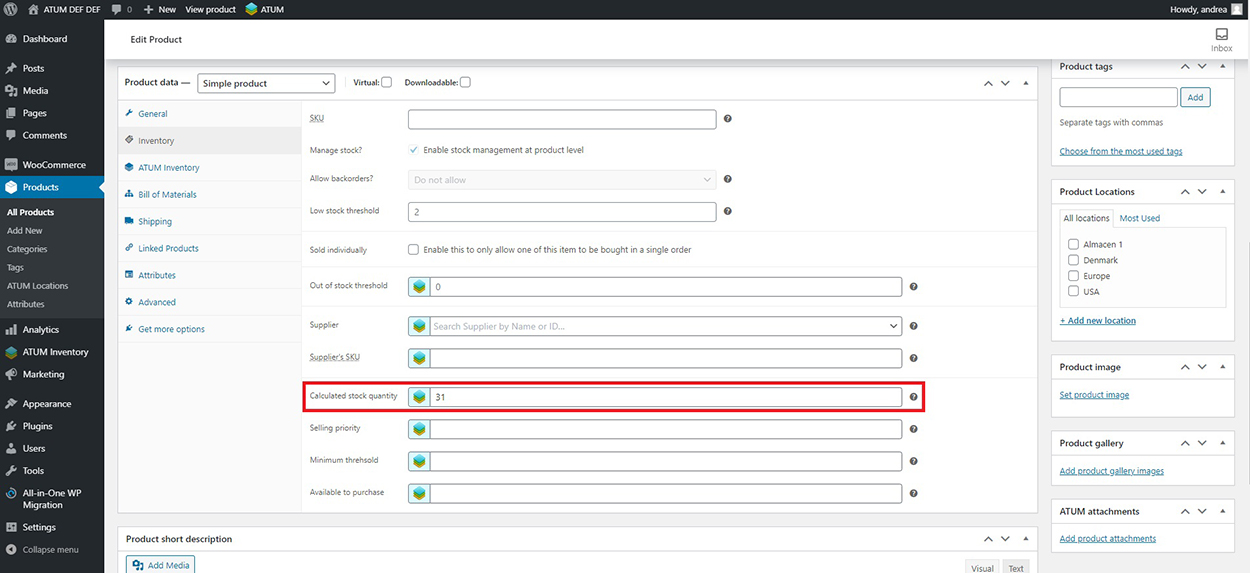

Next, go to the product and observe that we need 1 product part and 1 raw material to create one unit of product.

Now go to the Inventory section of the product, and you will see that the calculated automatically stock quantity is the sum of both inventories of each BOM. In this case, is 31.

SCENARIO 3. When the product and its BOMs are not Multi-Inventory, but a nested BOM is.

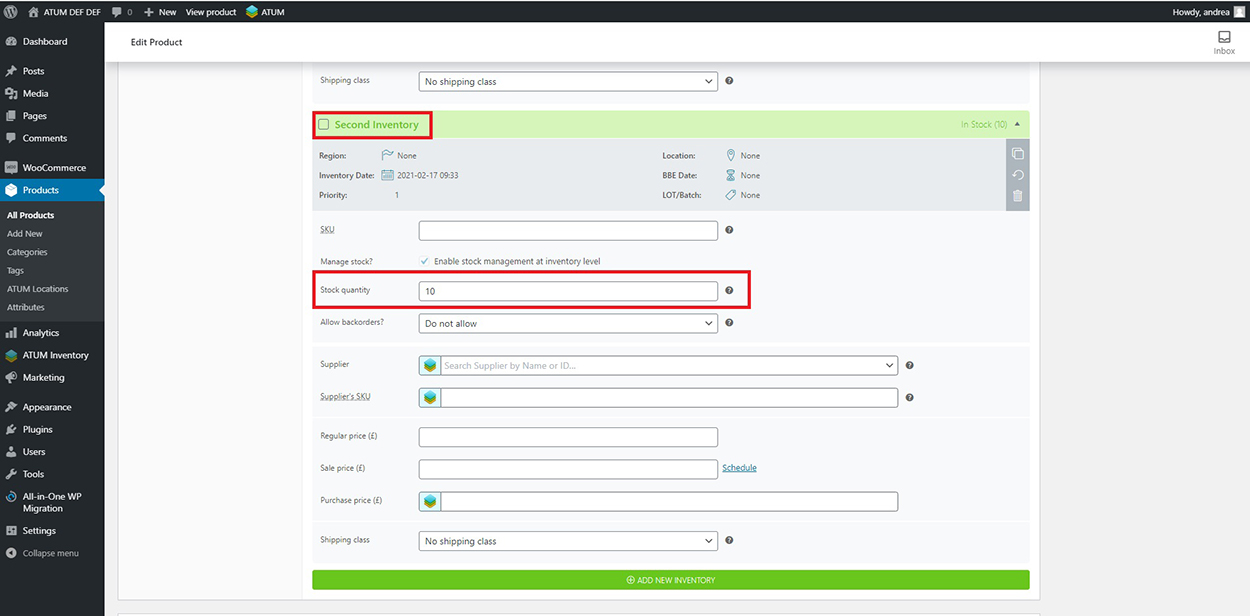

Go to the multi-inventory nested BOM. In this case, is a nested Raw Material that belongs to a Product Part. Observe the stock quantity value in inventories of the Product Part:

MAIN INVENTORY: 5

SECOND INVENTORY: 10

In this case, the total stock quantity of the raw material is 15 as it is the sum of both inventories.

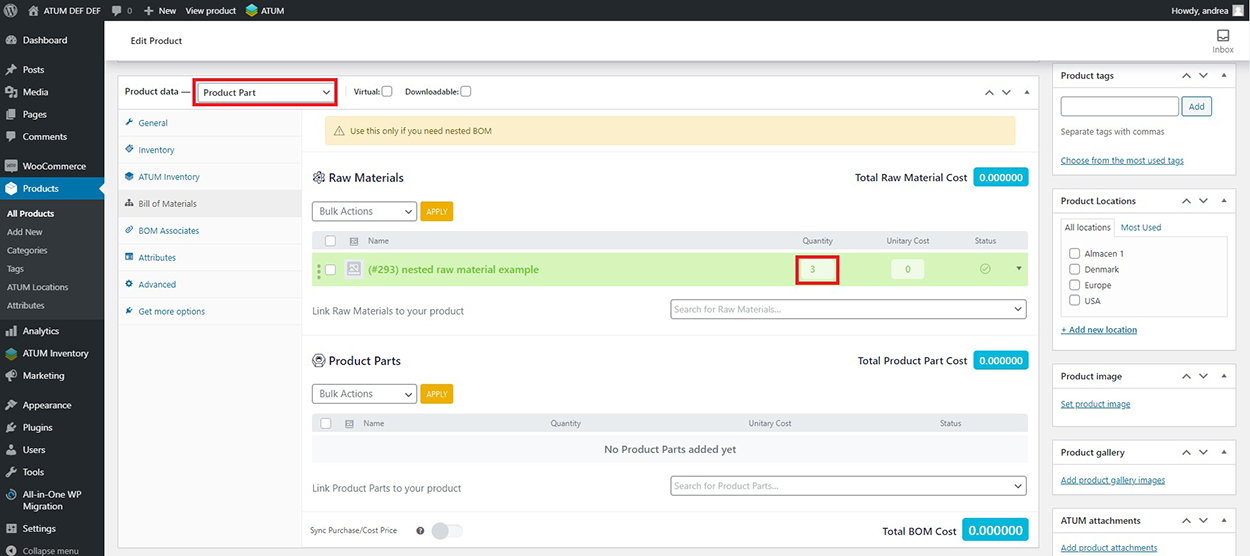

Next, go to the product part to which that nested raw material belongs. Observe that to create one product part we need 3 units of the nested raw material.

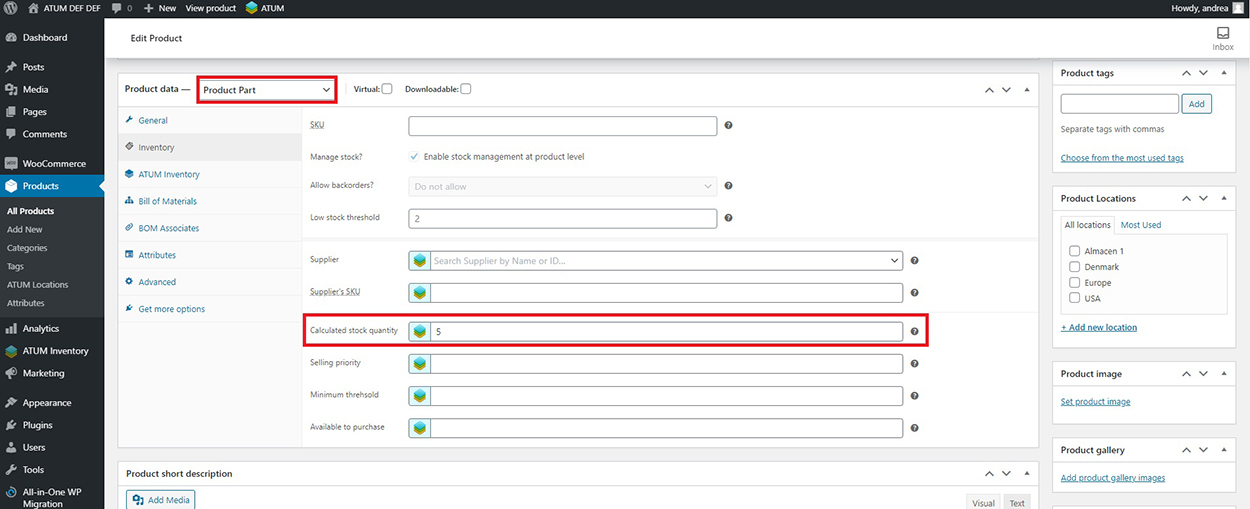

For that reason, the calculated stock quantity of the Product Part will be 5.

Therefore, the calculated stock quantity of the product will be 5 too.