When you enable the BOM Stock Control, the ATUM Product Levels calculate the stock of your products automatically looking at the associated available raw materials and products parts within. Let's explore several examples:

Example 1 – ONE product associated with only ONE BOM.

We associated Product A with 1 unit of Raw Material A.

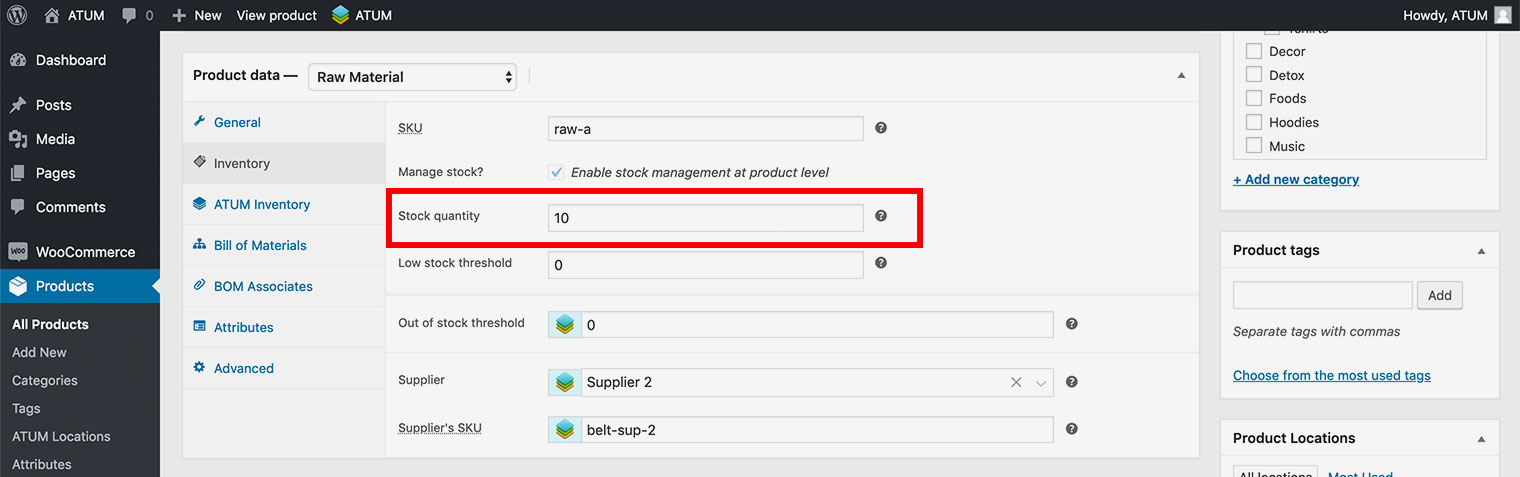

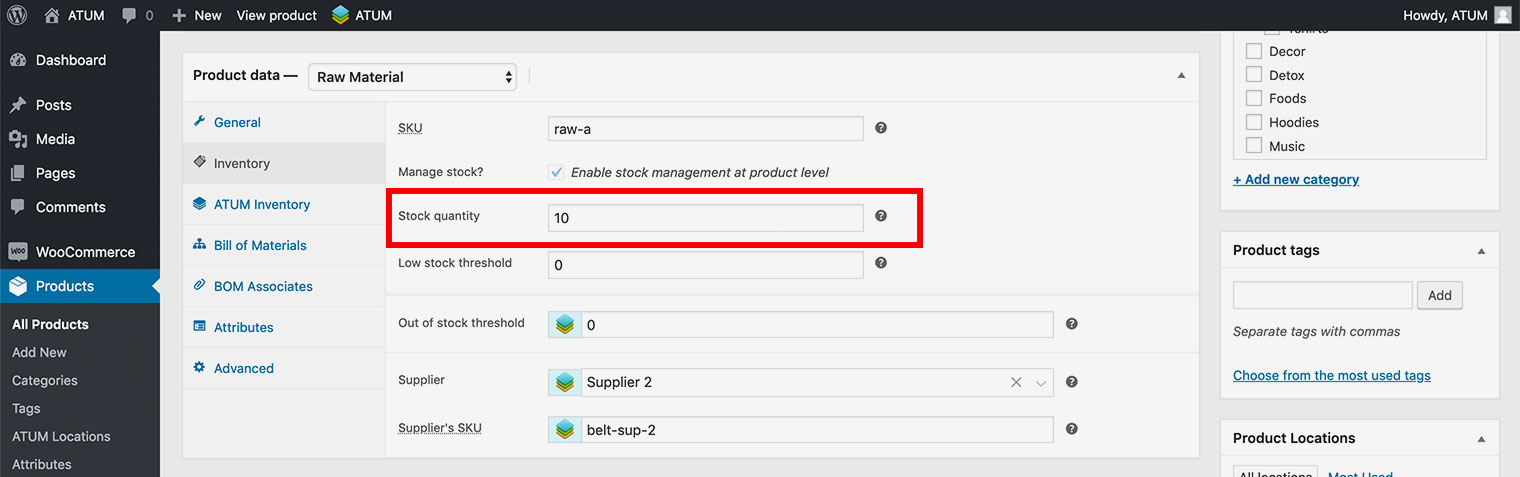

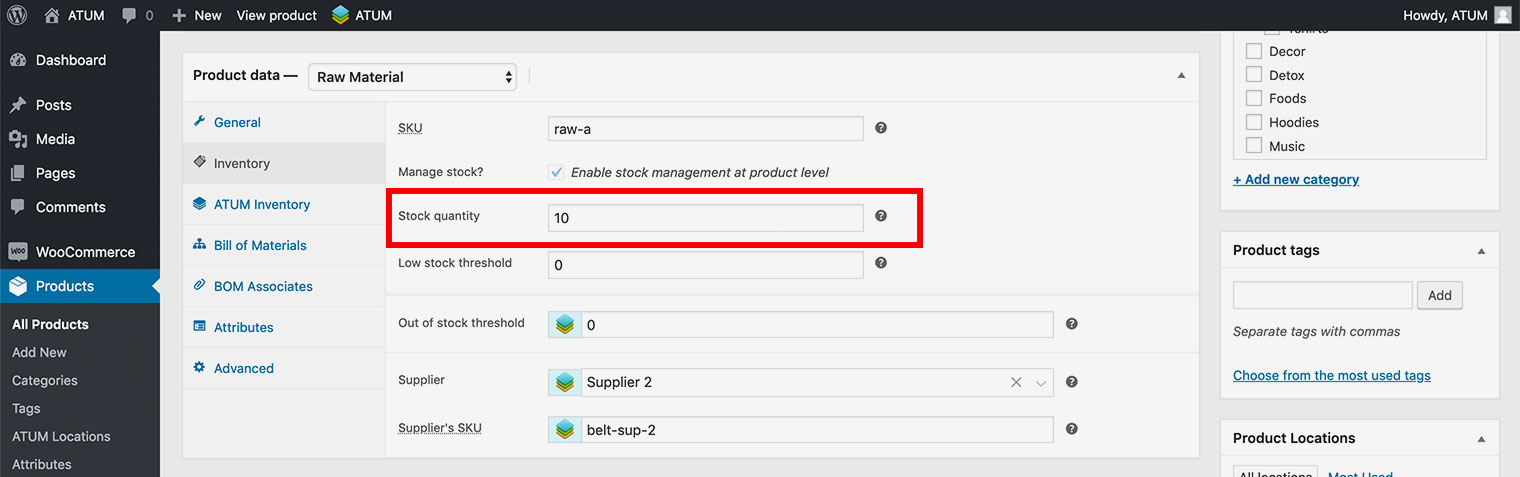

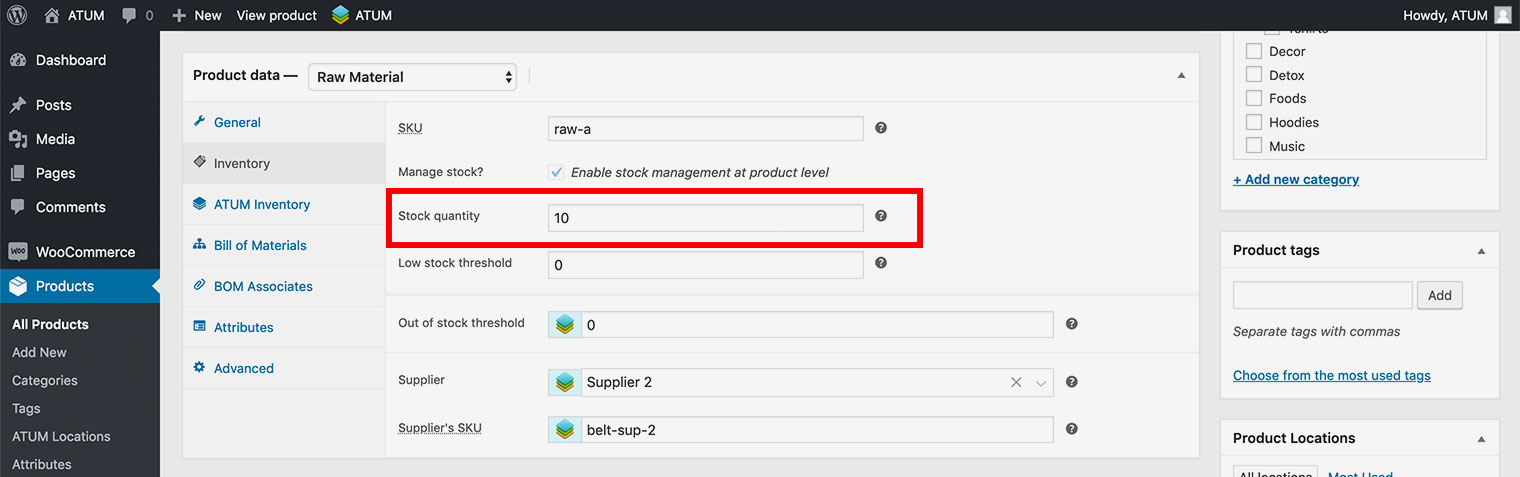

- Let’s create a Raw Material A with a Stock Quantity of 10.

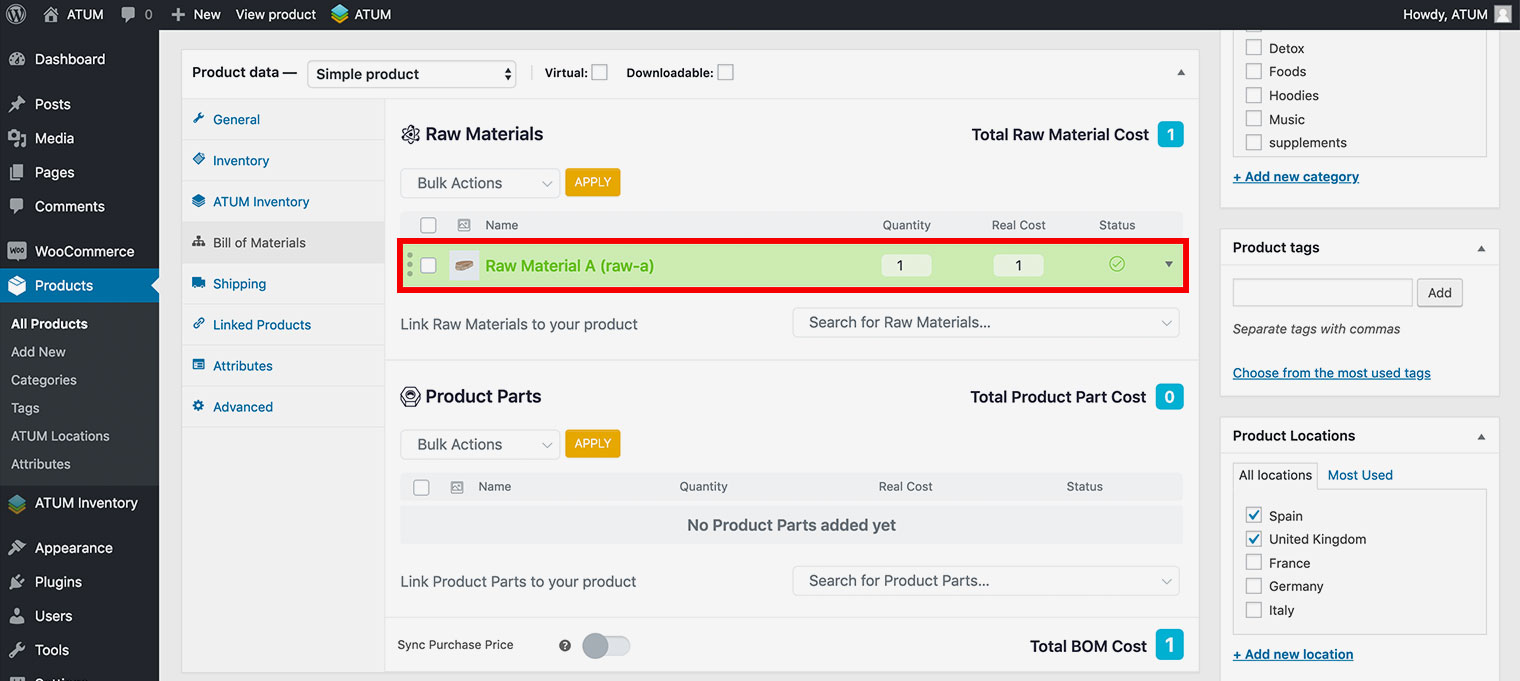

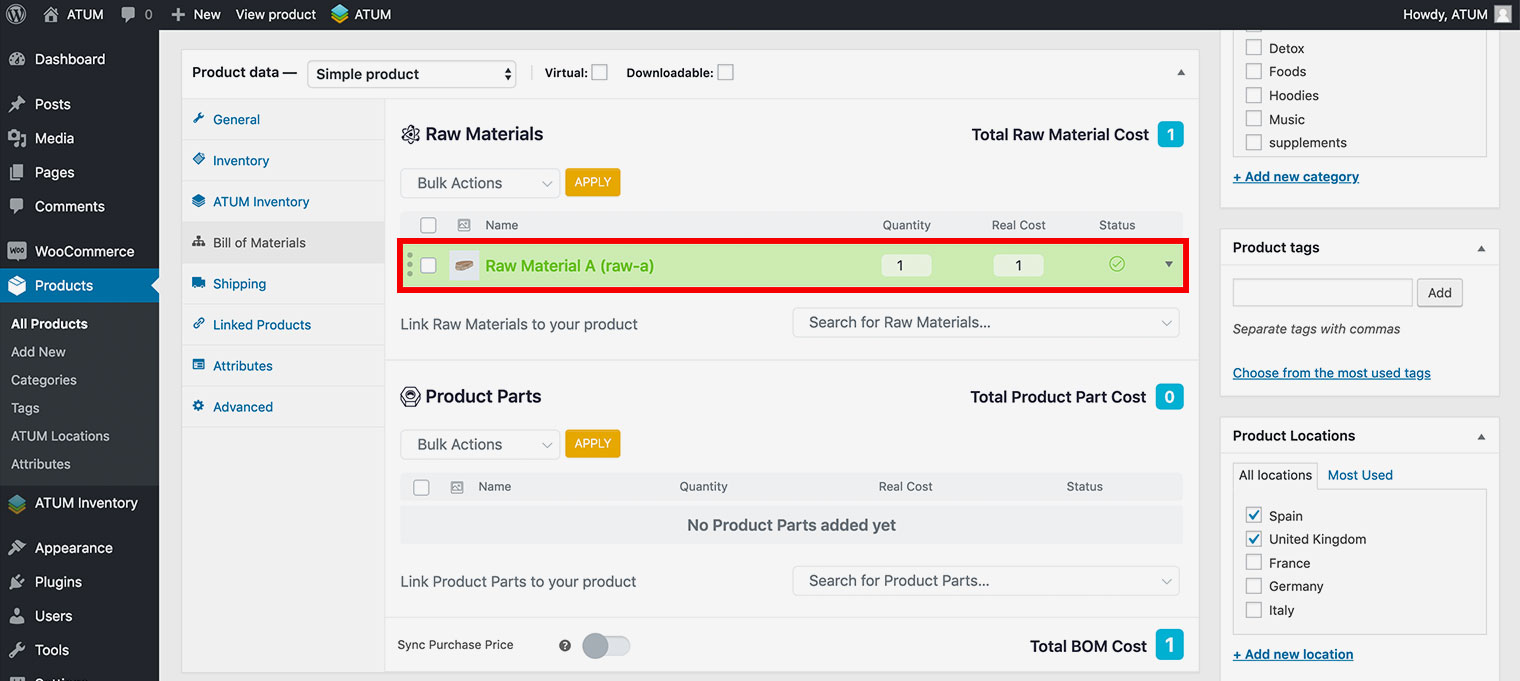

- Now we are going to add 1 unit of Raw Material A to the Bill of Materials of Product A.

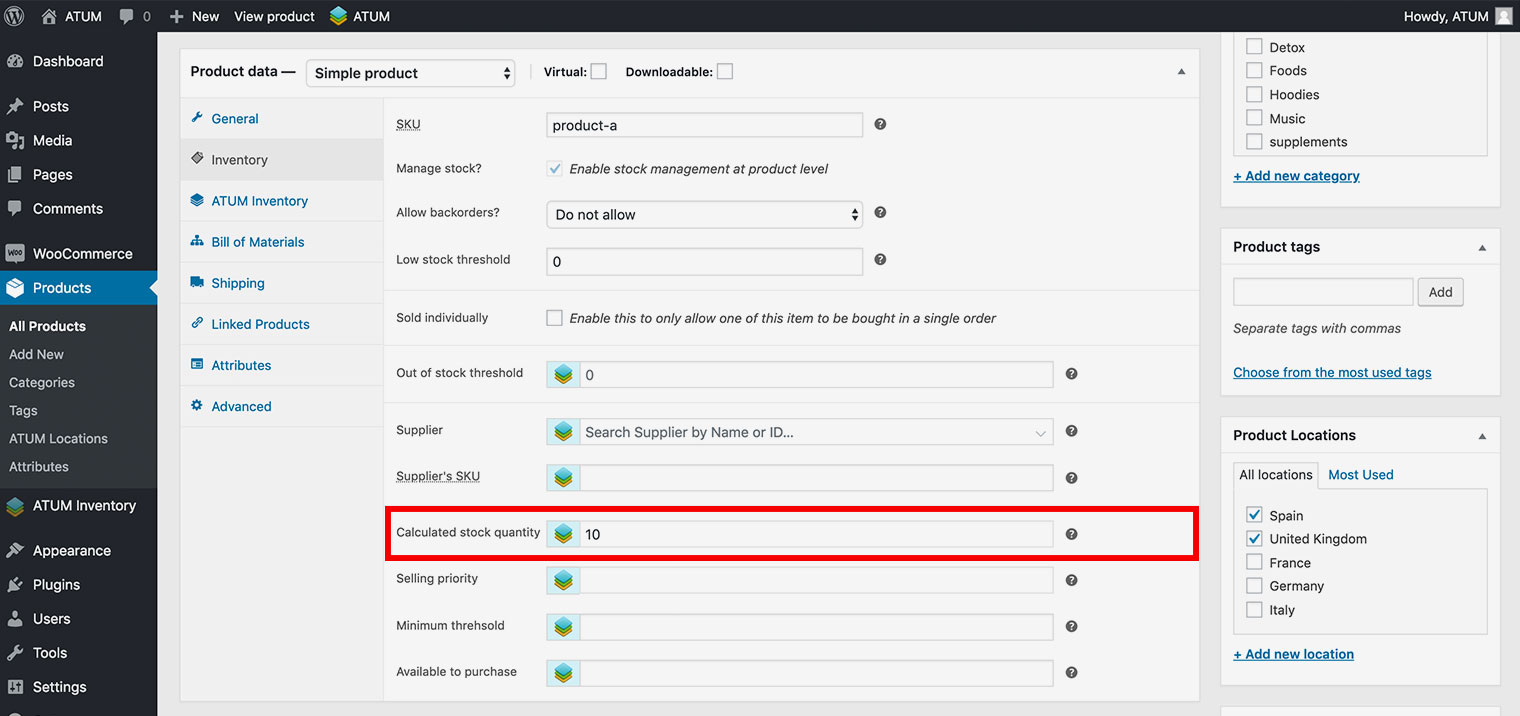

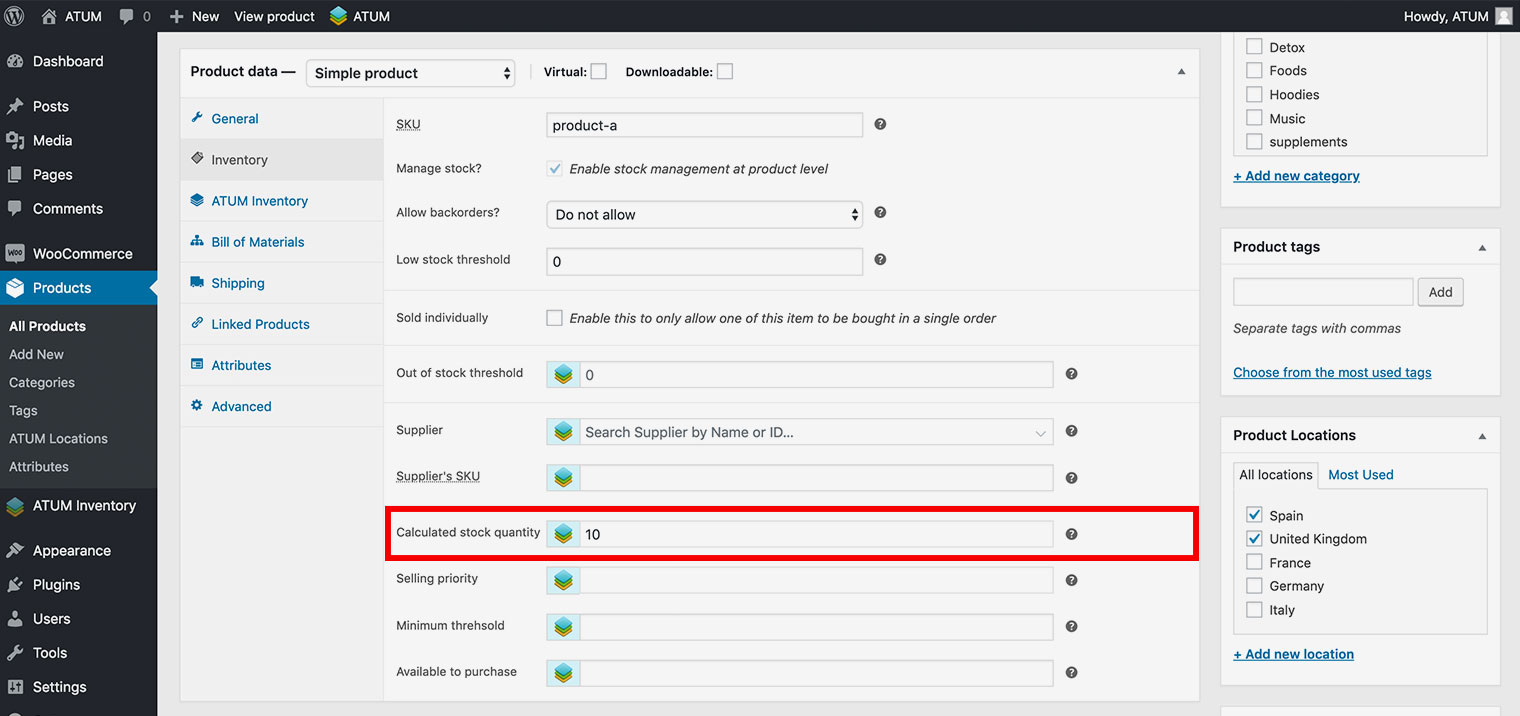

- Once we add the BOM and update the product, the stock quantity field in the inventory tab is replaced by the calculated stock quantity. In this example the calculated stock for Product A is 10 because each unit of Product A uses one unit of the Raw Material A, so the calculated stock of Product A equals the stock of Raw Material A.

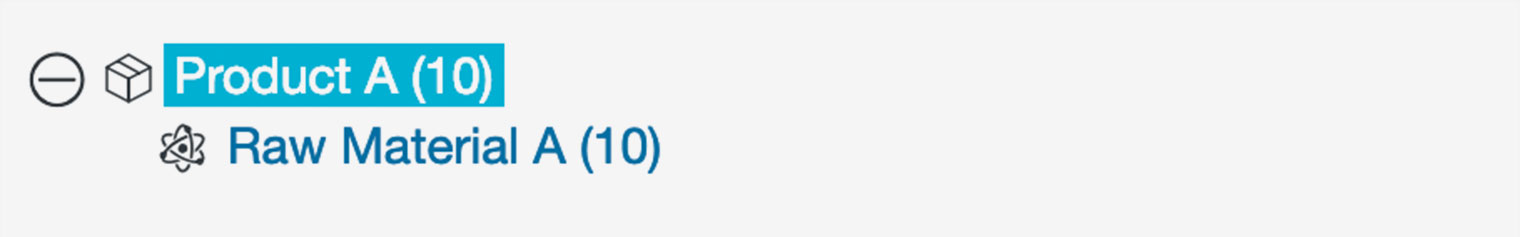

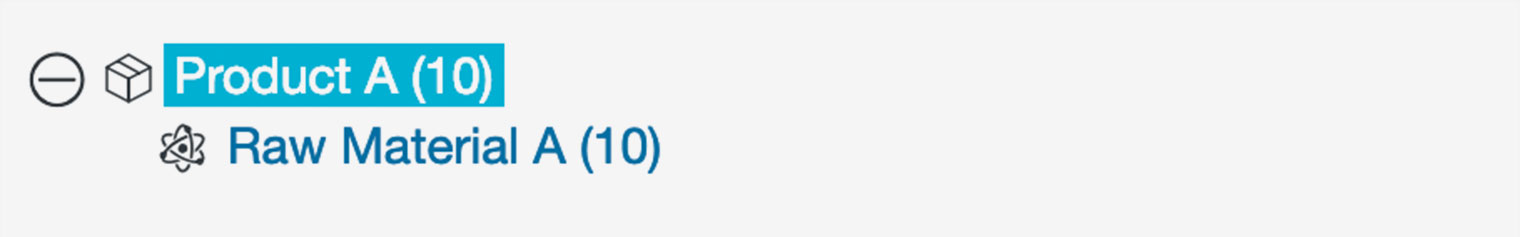

- We have the following BOM tree:

Example 2 – ONE product with more than one unit of ONE BOM

We associated Product A with 2 units of Raw Material A.

- Let’s create a Raw Material A with a Stock Quantity of 10.

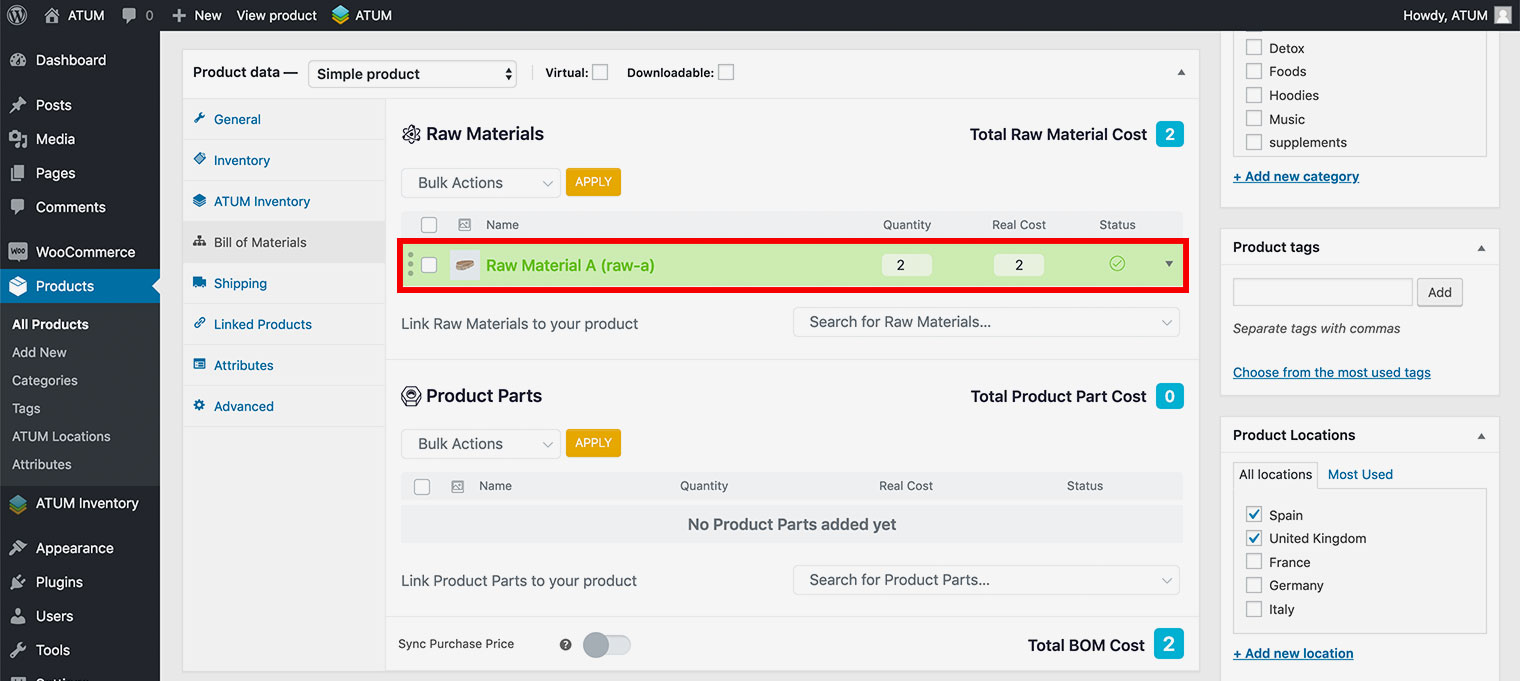

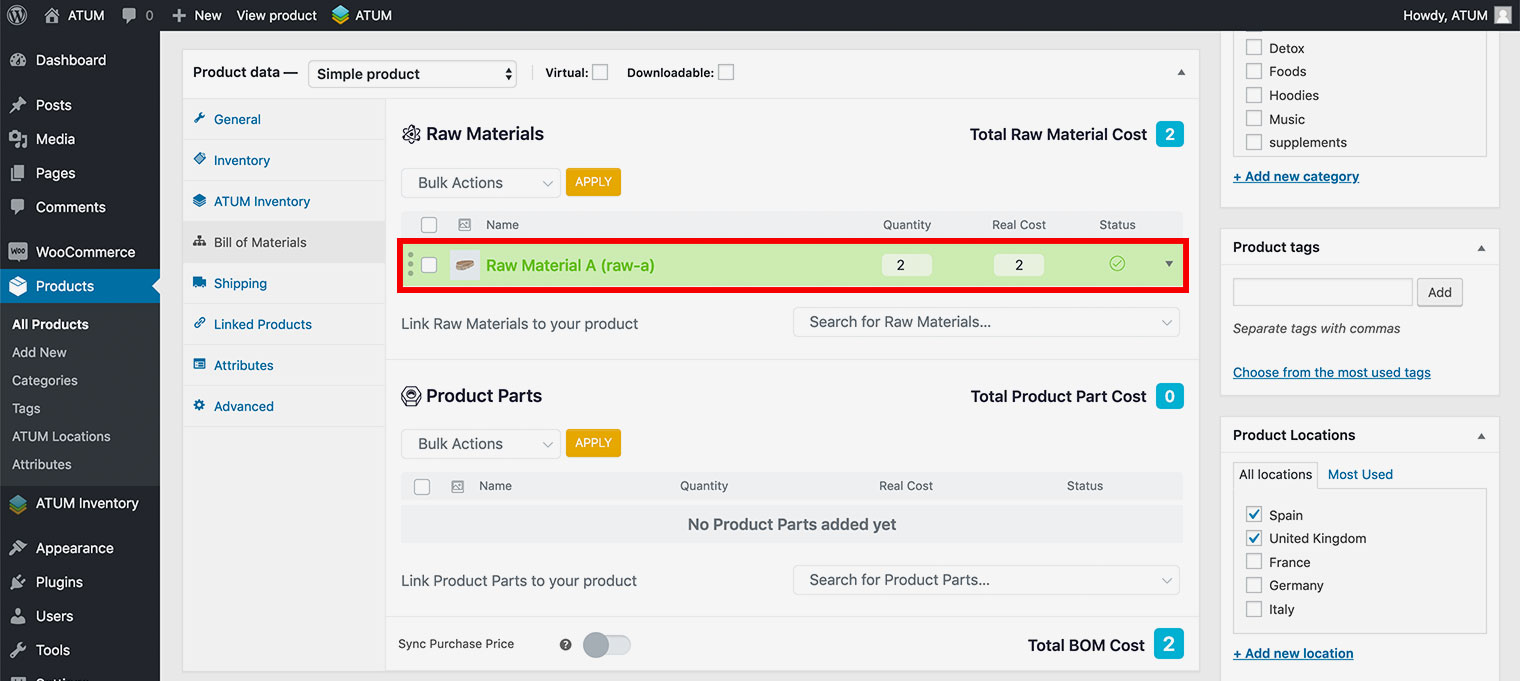

- Now we are going to add 2 units of Raw Material A to the Bill of Materials of Product A.

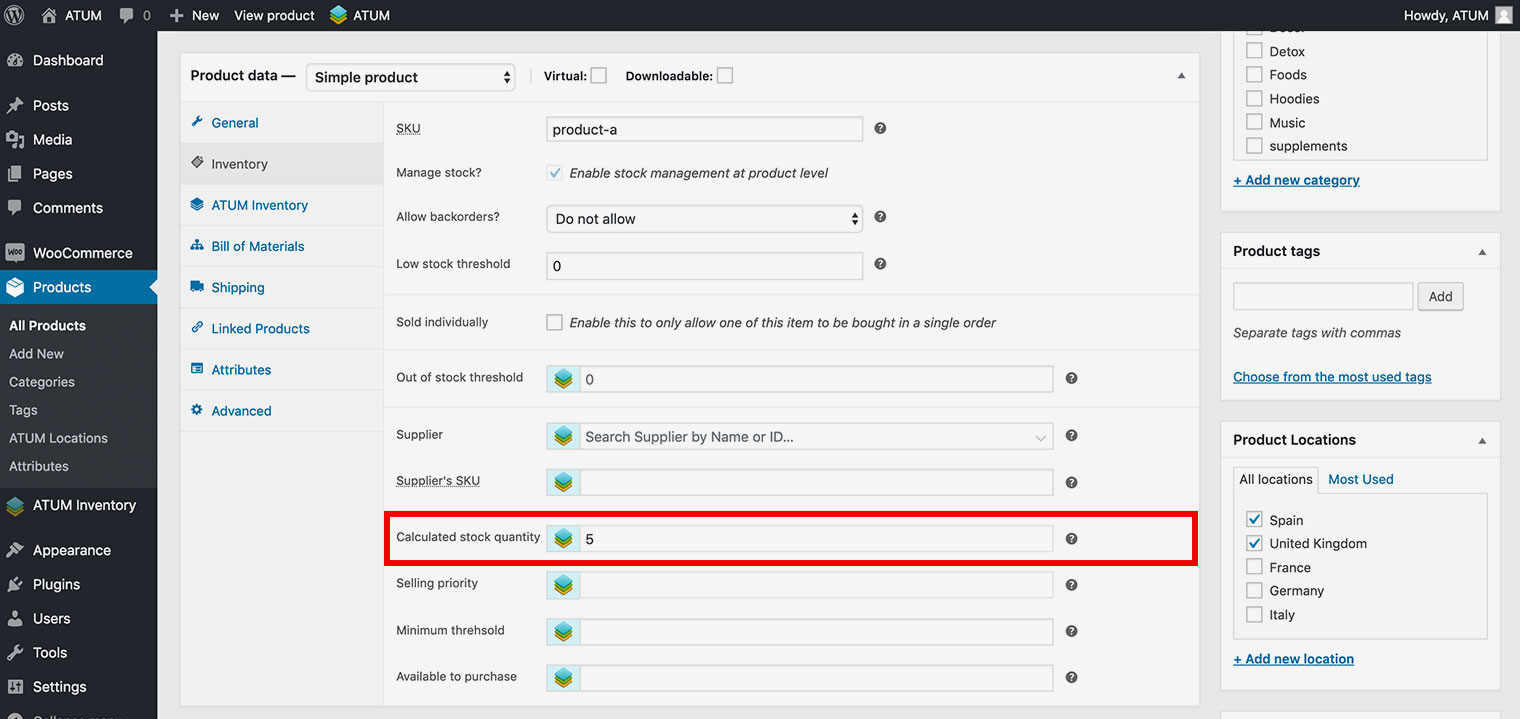

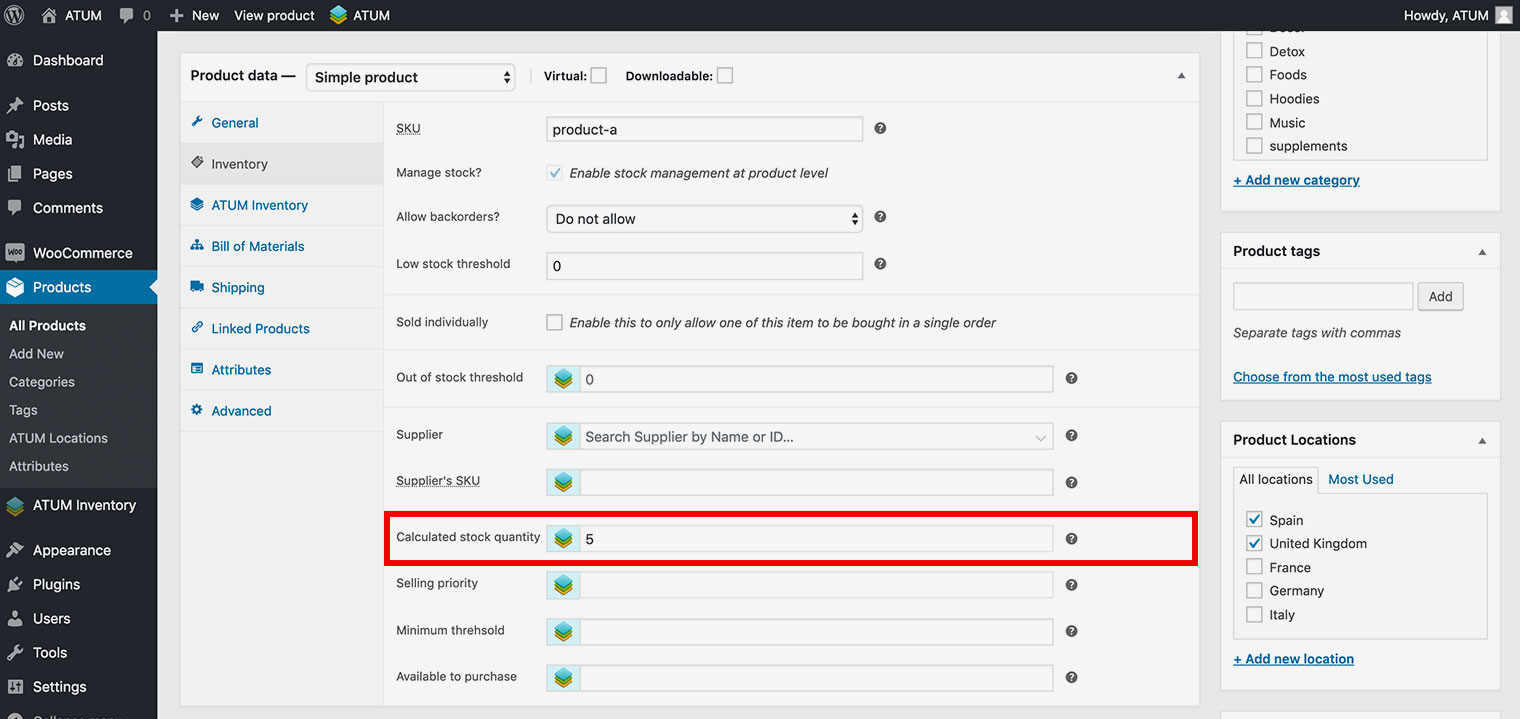

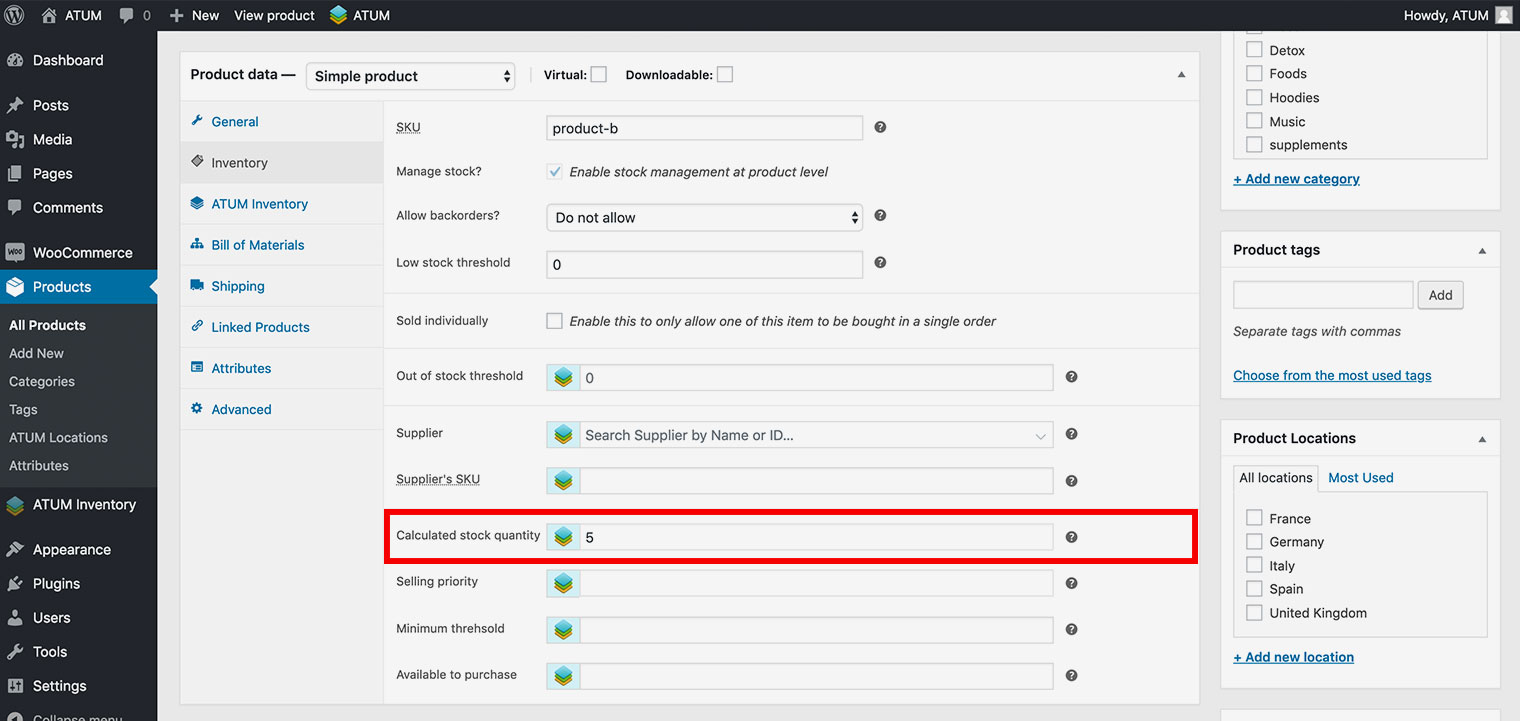

- Once we add the BOM and update the product, the stock quantity field in the inventory tab is replaced by the calculated stock quantity. In this example, the calculated stock for Product A is 5, because each unit of Product A uses two units of the Raw Material A.

- We have the following BOM tree:

stock of Product A = Raw Material A / 3.

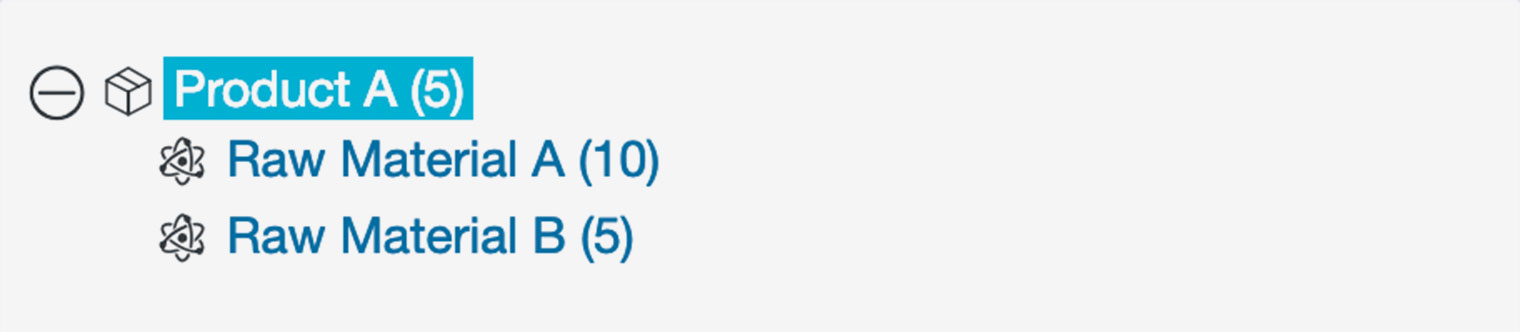

Example 3 - ONE product with TWO different BOM.

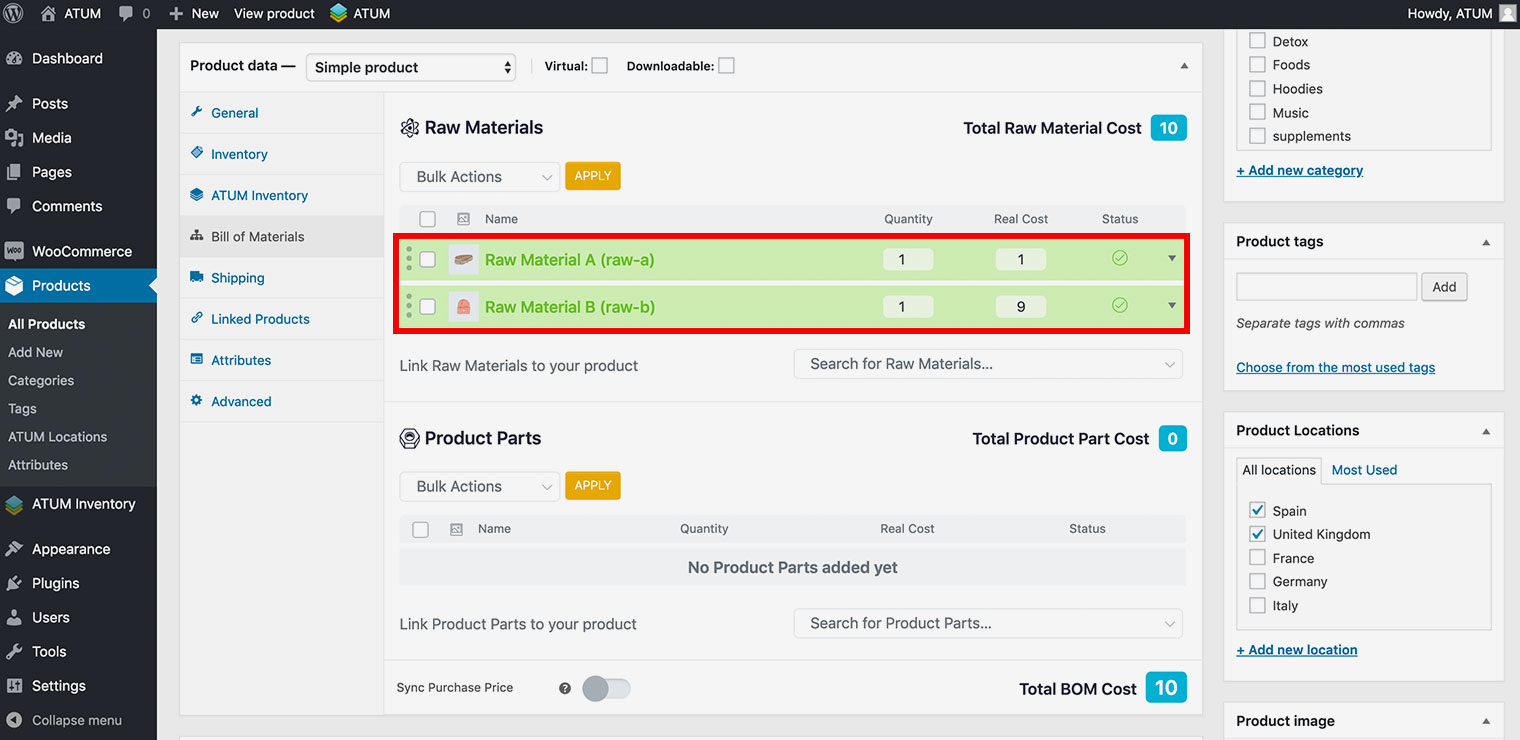

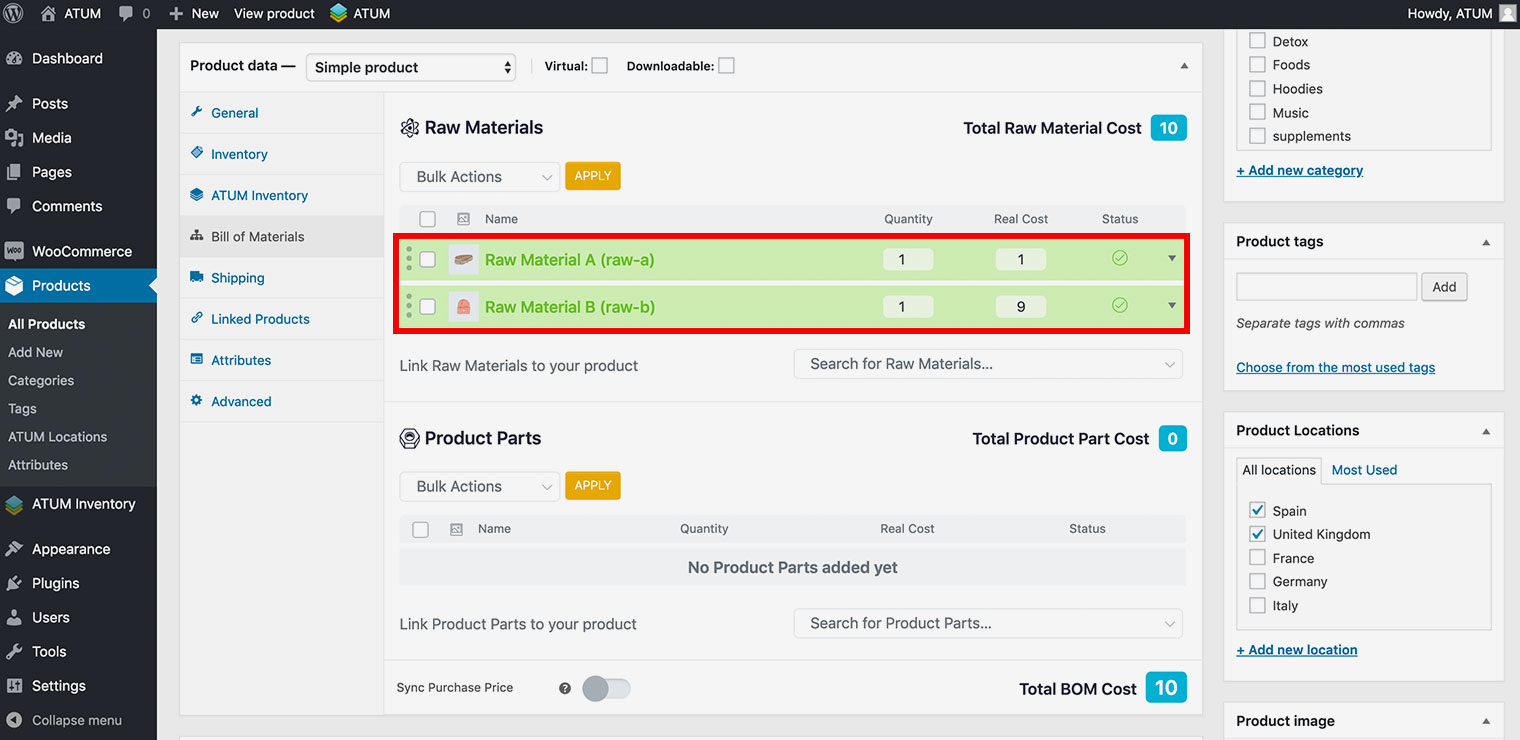

We associate Product A with 1 unit of Raw Material A and 1 unit of Raw Material B.

- Let’s create a Raw Material A with a Stock Quantity of 10.

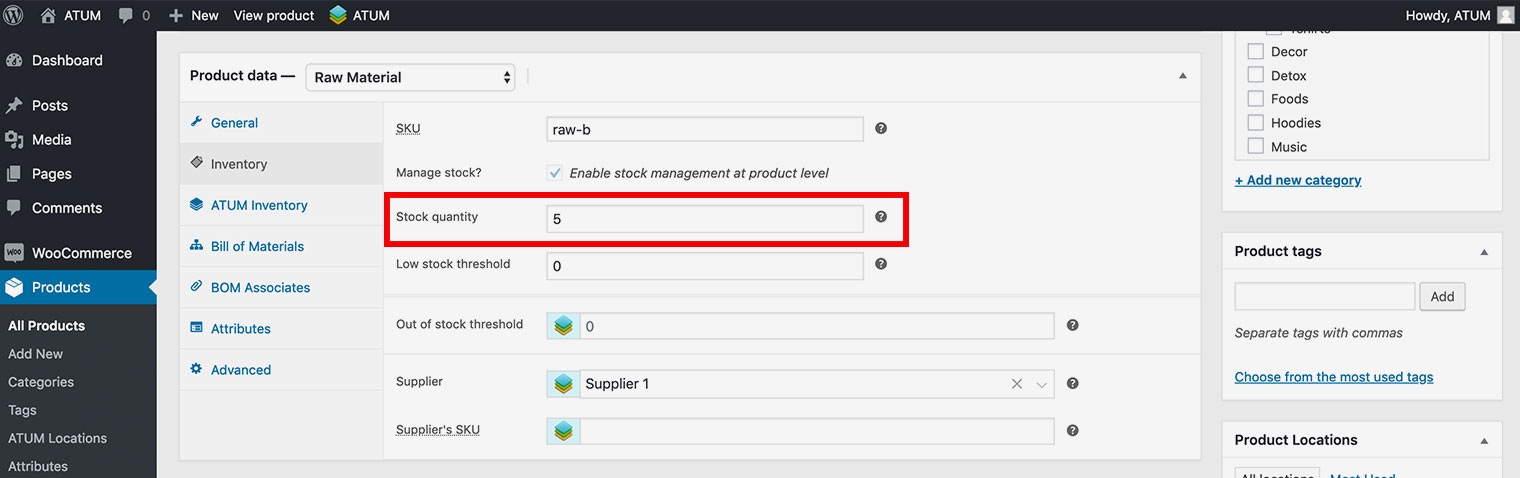

- And let’s create Raw Material B with a Stock Quantity of 5.

- Now we add 1 unit of each Raw Material to the Bill of Materials of Product A.

- Once we add the BOM and update the product, the stock quantity field in the inventory tab gets replaced by the calculated stock quantity field. In this example the calculated stock for Product A is 5, because when 5 units sell, the Raw Material B will run out of stock and there will not be enough to produce the Product A.

- We have the following BOM tree:

Example 4 - ONE product with ONE BOM that contains a nested BOM within.

We associate Product A with 1 unit of Raw Material A. Then we associate this Raw Material A with 1 unit of Nested Raw Material.

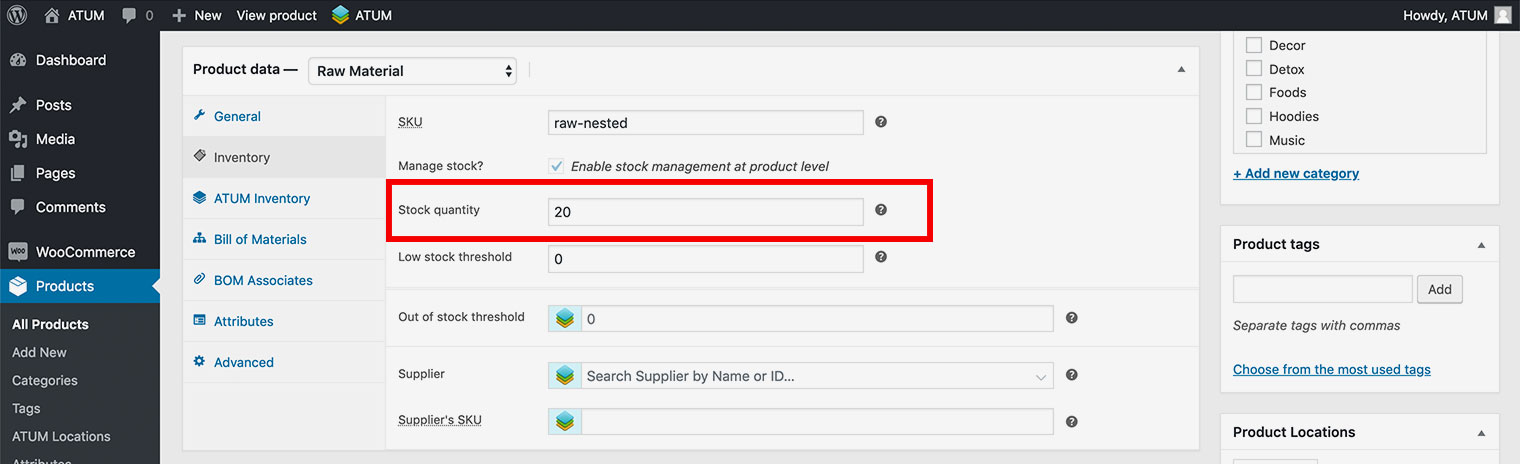

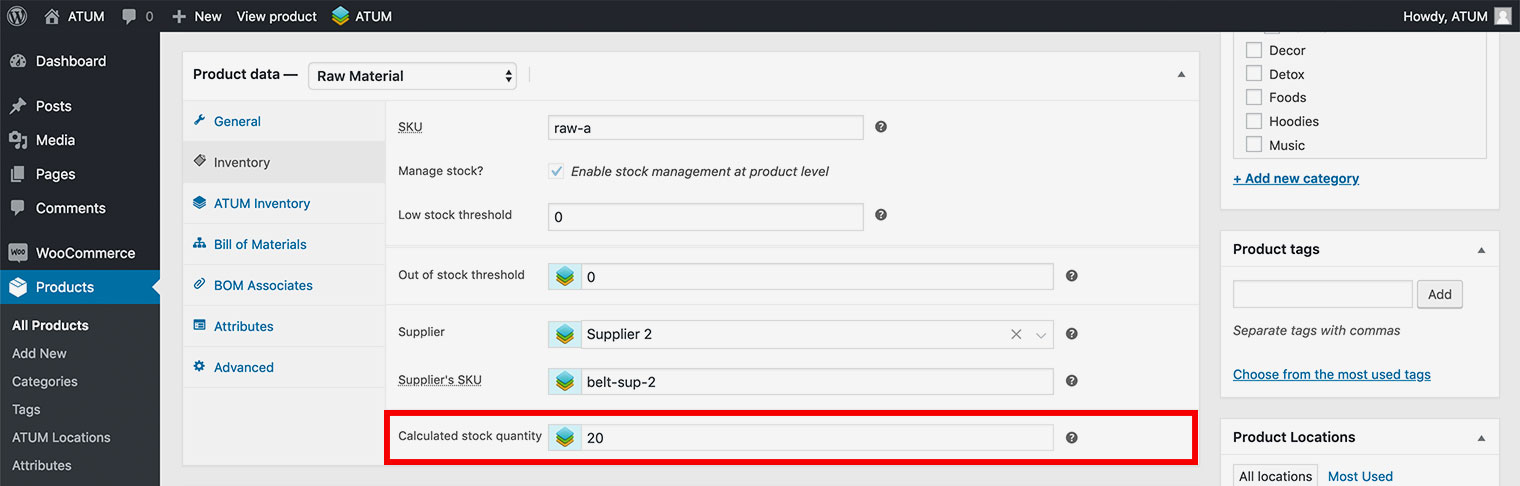

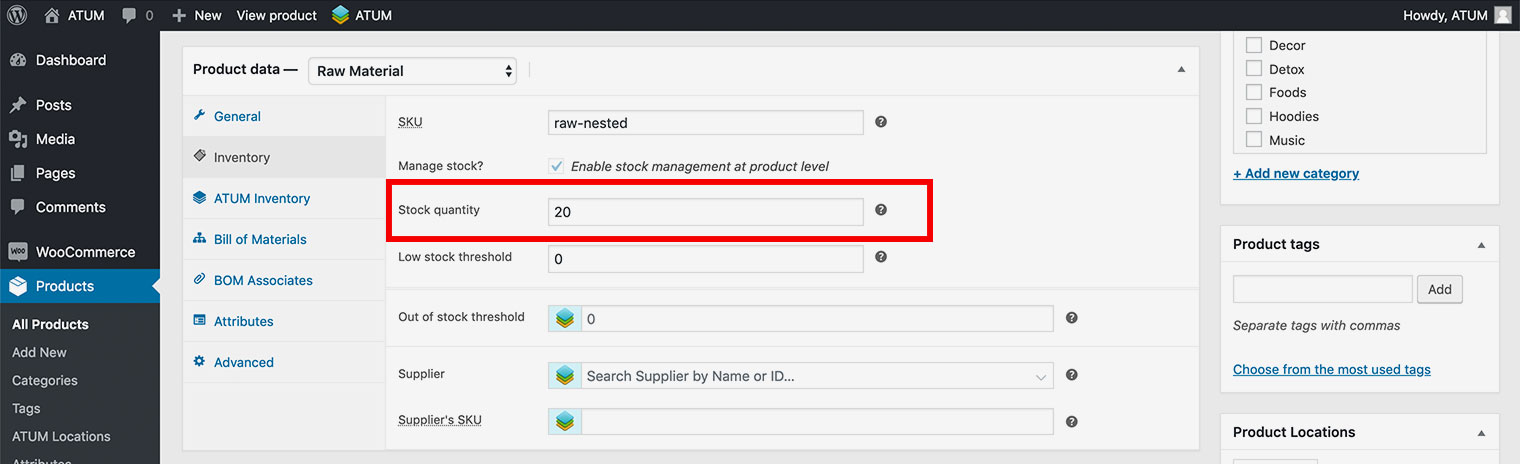

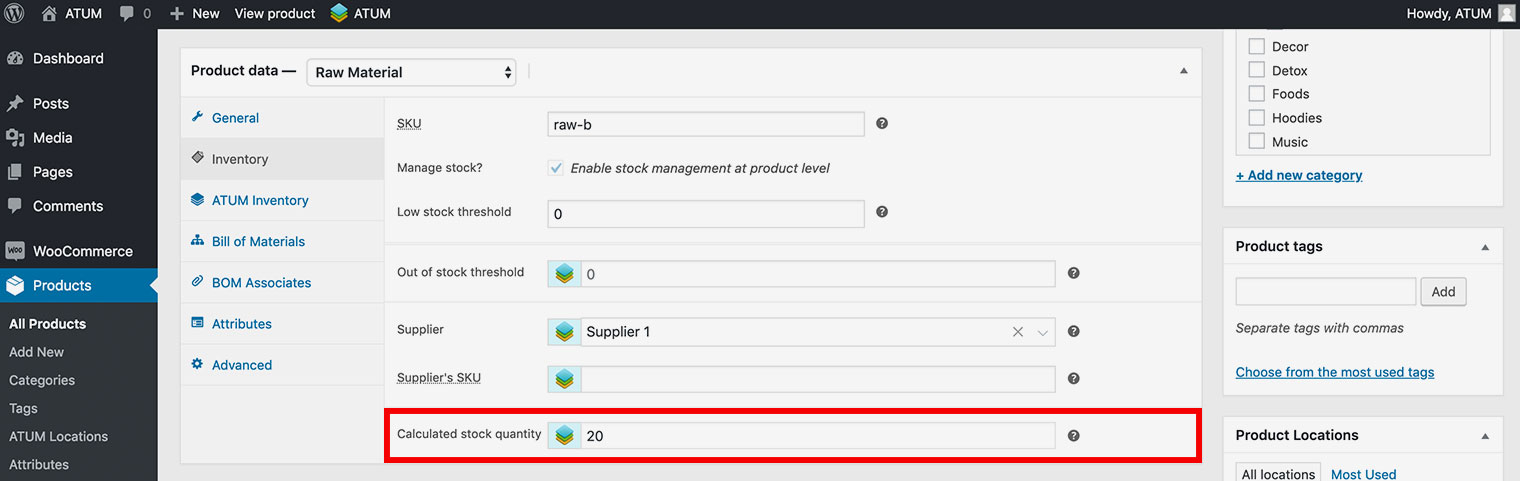

- Let’s create a Nested Raw Material with a Stock Quantity of 20.

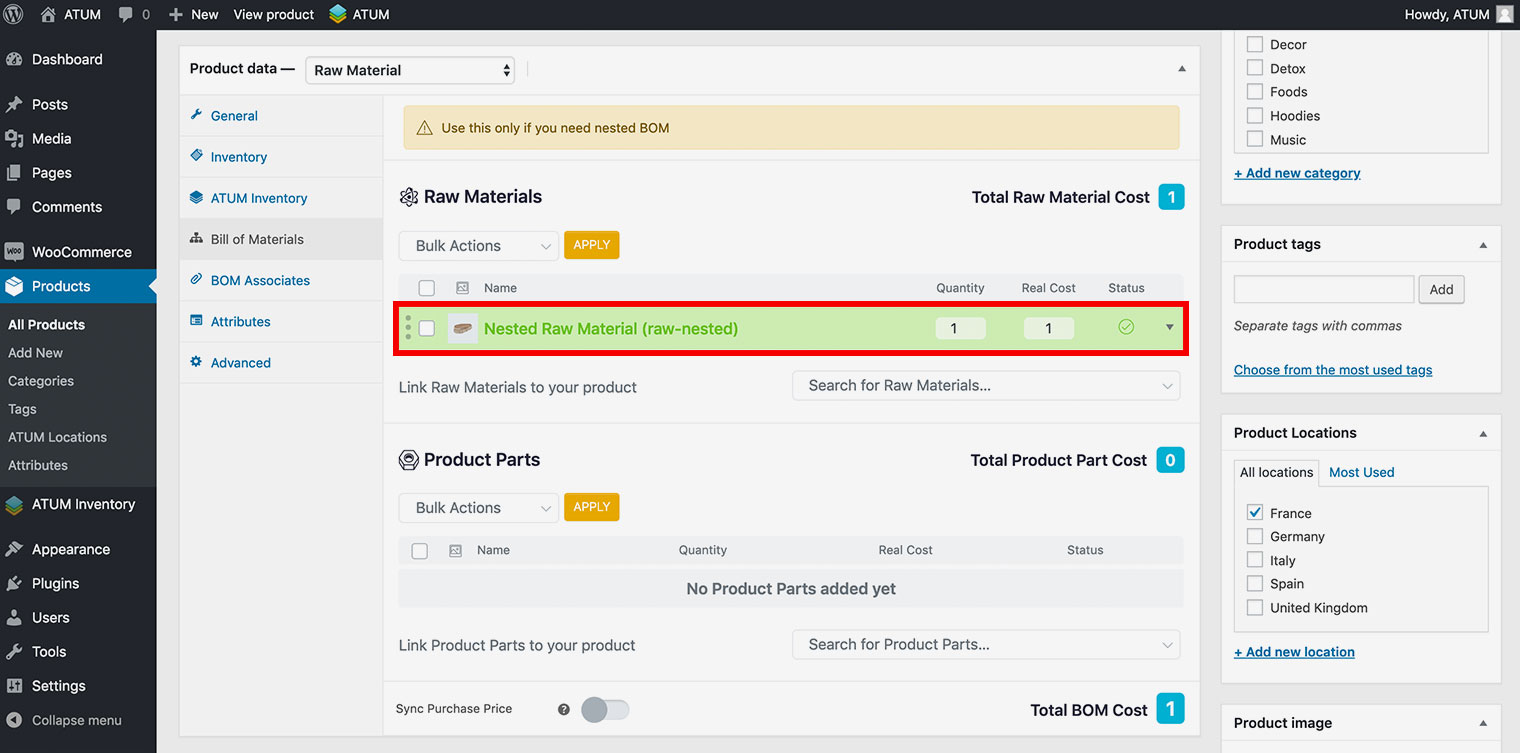

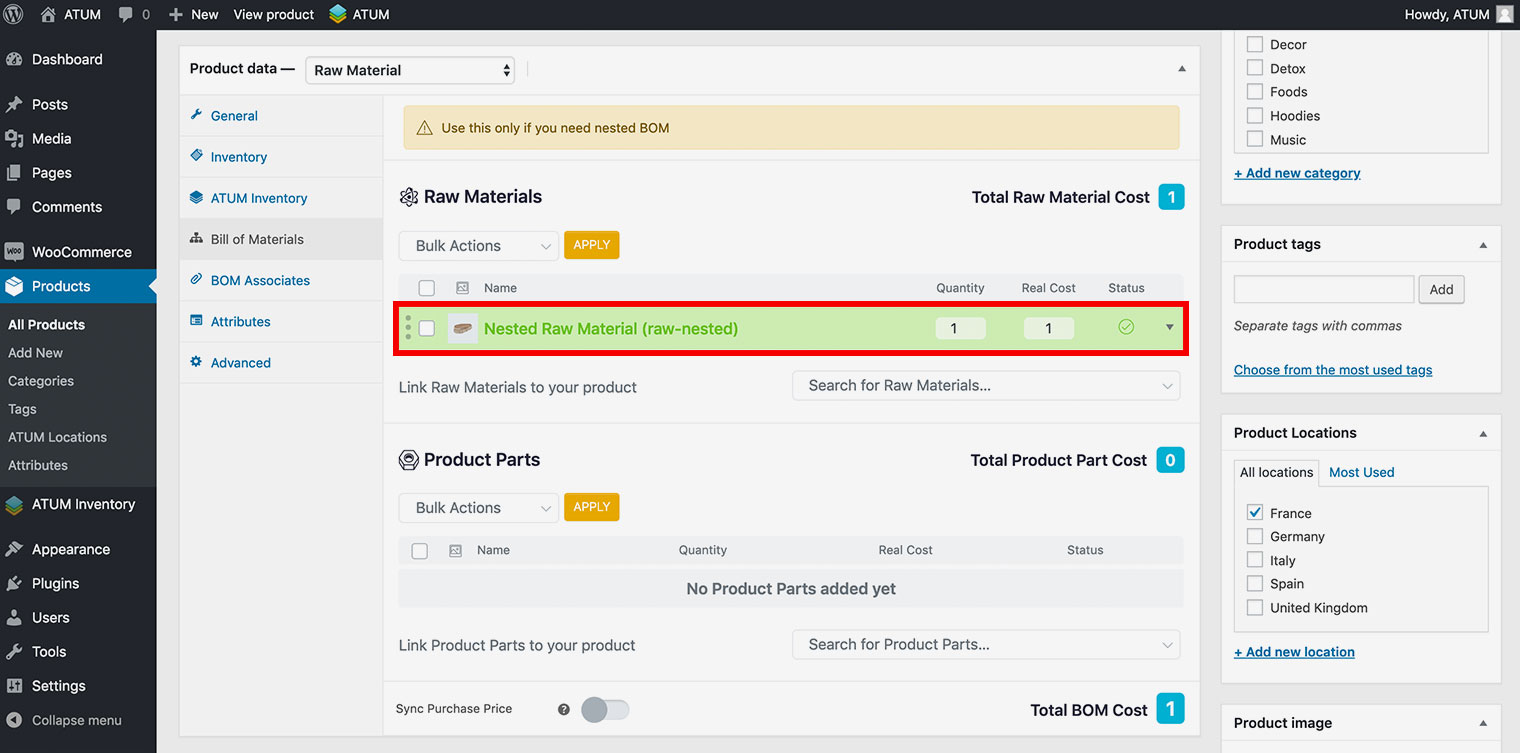

- Now we are going to add 1 unit of the Nested Raw Material to the Bill of Materials of the Raw Material A.

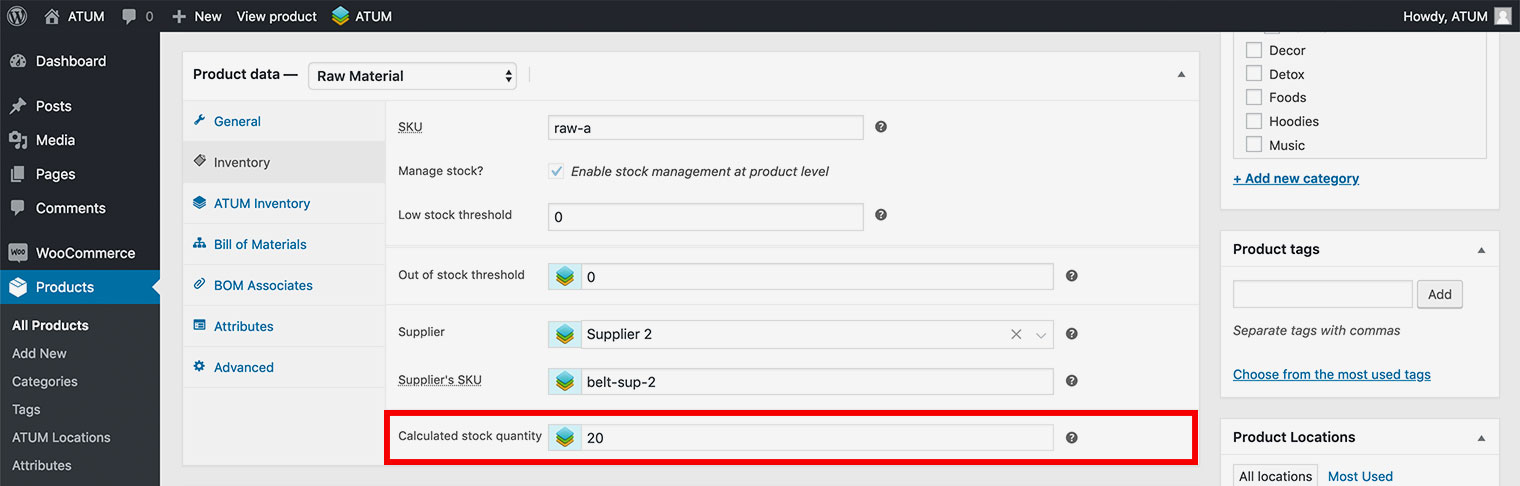

- Once you add the BOM and update the Raw Material, the stock quantity field in the inventory tab gets replaced by the calculated stock quantity field. In this example, the calculated stock for Raw Material A is 20 (same as Nested Raw Material).

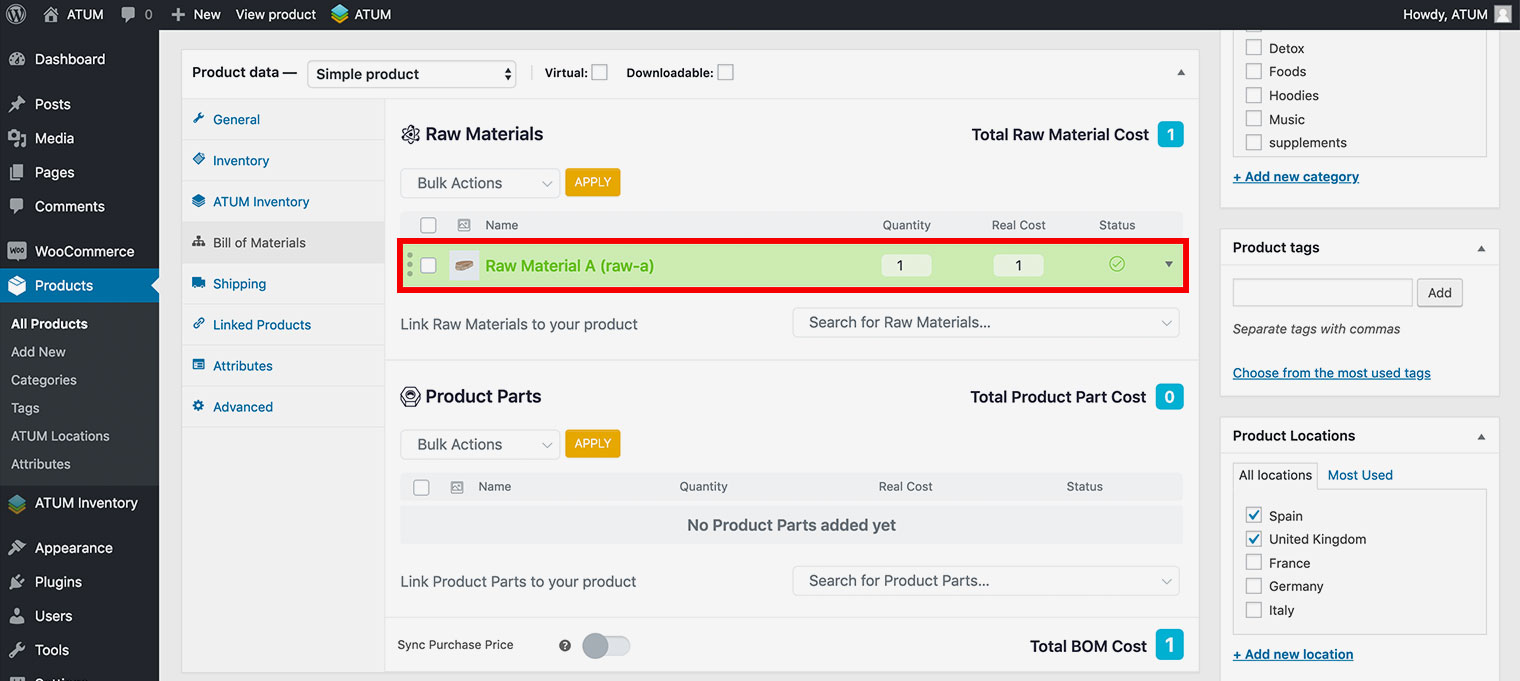

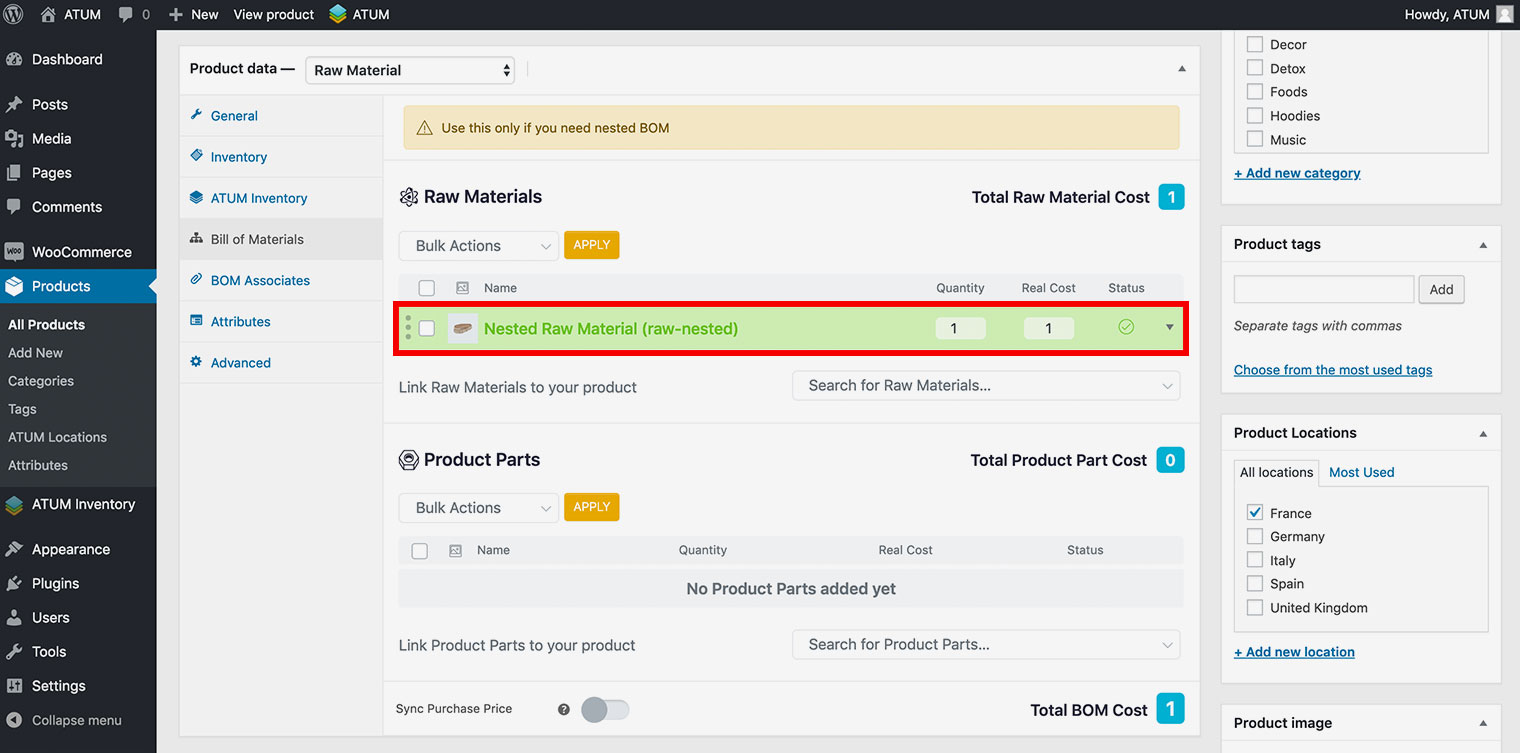

- Now, let’s add 1 unit of Raw Material A to the Bill of Materials of the Product A.

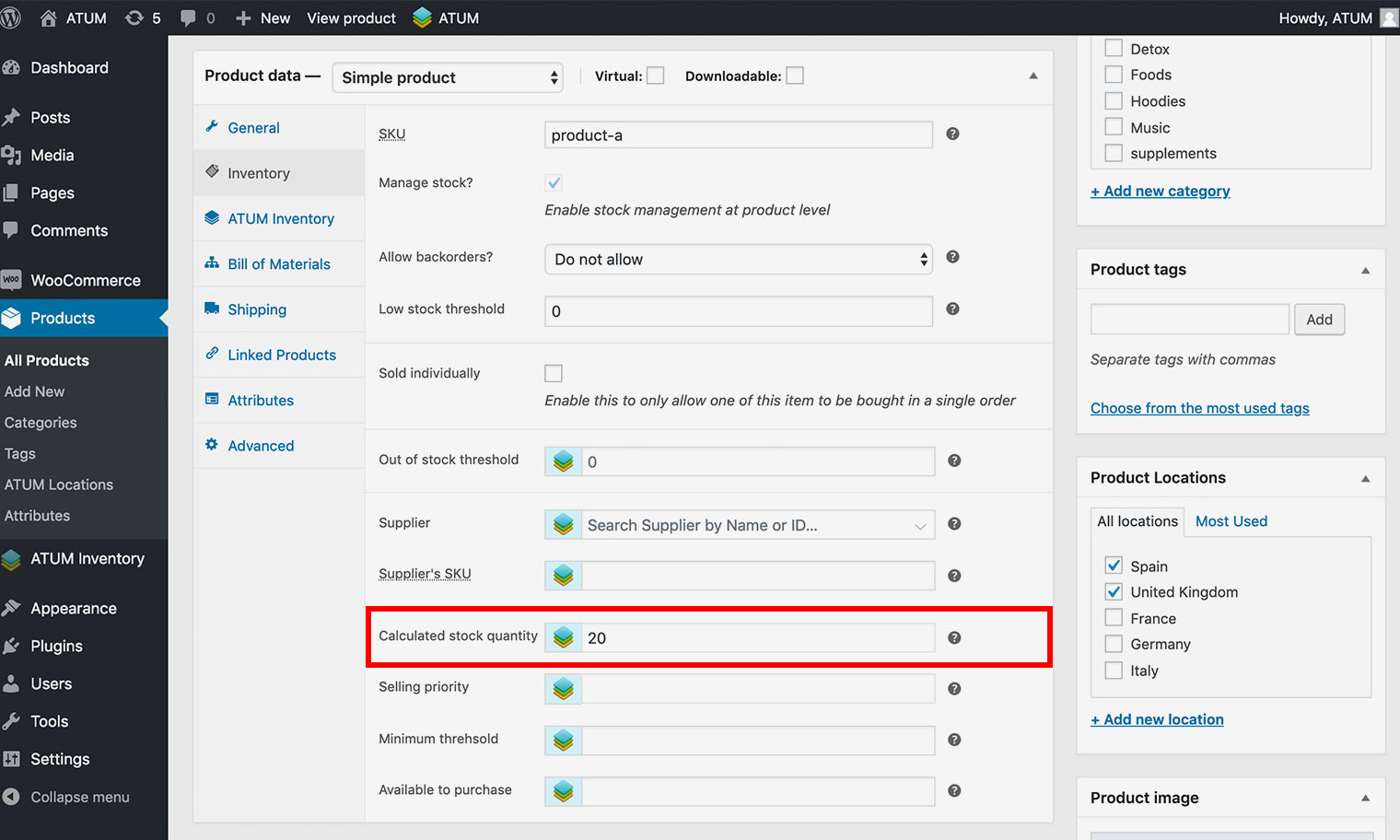

- Once you add the BOM and update the Product, the stock quantity field in the inventory tab gets replaced by the calculated stock quantity field. In this example, the calculated stock for Product A is 20 (same as Raw Material A).

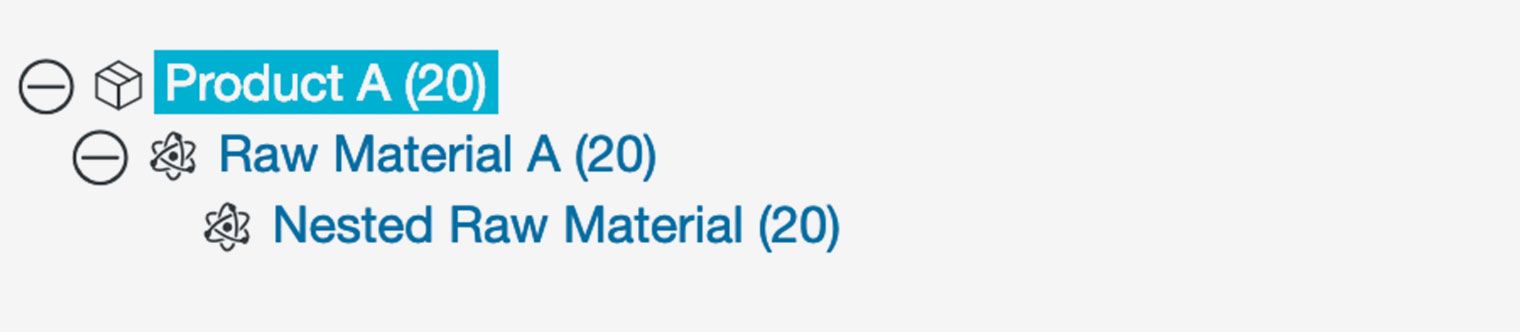

- We have the following BOM tree:

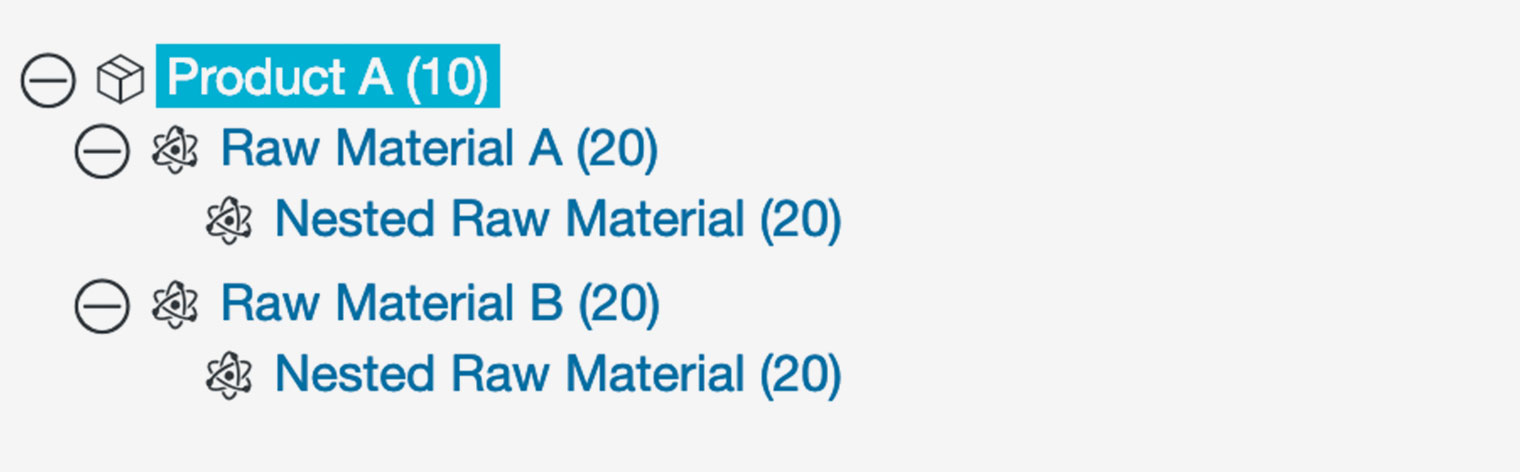

Example 5 - ONE product with several BOMs, that are associated with the same nested BOM.

Product A associated with 1 unit of Raw Material A and 1 unit of Raw Material B, both raw materials are associated with 1 unit of the same Nested Raw Material.

- Let’s create a Nested Raw Material with a Stock Quantity of 20.

- Now we add 1 unit of the Nested Raw Material to the Bill of Materials of the Raw Material A.

- Once you add the BOM and update the Raw Material, the stock quantity field in the inventory tab replaces the calculated stock quantity field. In this example, the calculated stock for Raw Material A is 20 (same as Nested Raw Material).

- Let’s add 1 unit of Nested Raw Material to the Bill of Materials of Raw Material B.

- Once you add the BOM and update the Raw Material, the stock quantity field in the inventory tab replaces the calculated stock quantity field. In this example, the calculated stock for Raw Material B is 20 (same as Nested Raw Material).

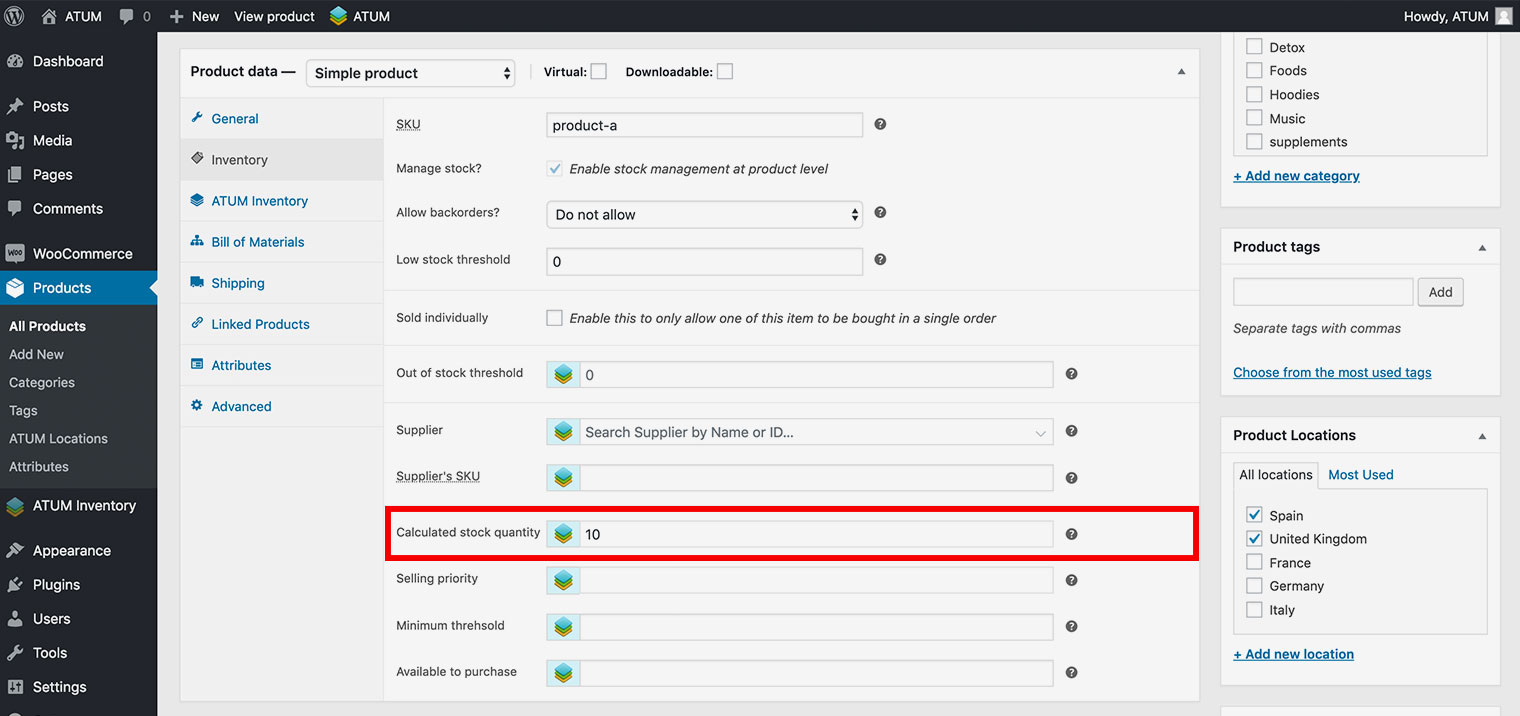

- Now we are going to add Raw Material A and Raw Material B to the Bill of Materials of Product A.

- Once you add the BOM and update the Product, the stock quantity field in the inventory tab replaces the calculated stock quantity field. In this example, the calculated stock of Product A is 10 because each unit of Product A needs 2 units of the Nested Raw Material so we have enough stock to create 10 Product A.

- We have the following BOM tree:

Example 6 - TWO products with the same BOM

We associate Product A with 1 unit of Raw Material A, and Product B with 2 units of Raw Material A.

- Let’s create a Raw Material A with a Stock Quantity of 10.

- Now we are going to add 1 unit of Raw Material A to the Bill of Materials of Product A.

- Once you add the BOM and update the Product, the stock quantity field in the inventory tab replaces the calculated stock quantity field. In this example, the calculated stock for the Product A is 10 (same as Raw Material A).

- Let’s add 2 units of Raw Material A to the Bill of Materials of Product B.

- Once you add the BOM and update the Product, the stock quantity field in the inventory tab replaces the calculated stock quantity field. In this example, the calculated stock for Product B is 5 (the stock of the Raw Material A divided by 2).

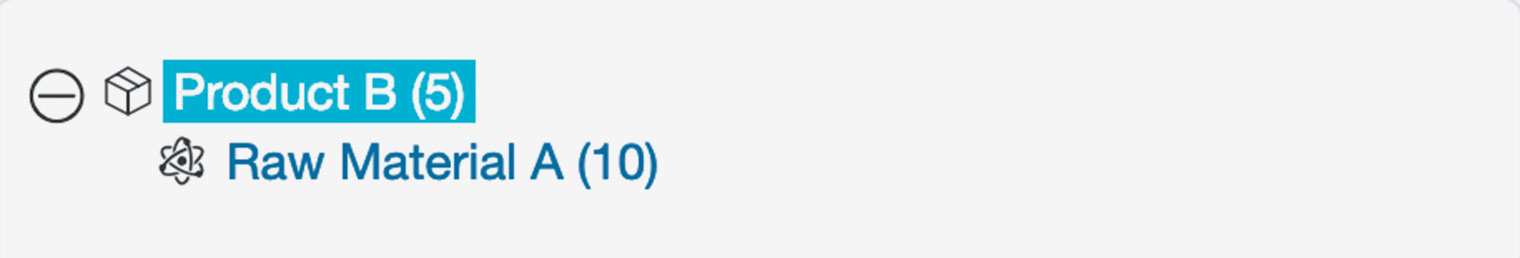

- We have the following BOM trees: